18-BC52D5-5

5

Installer’s Guide

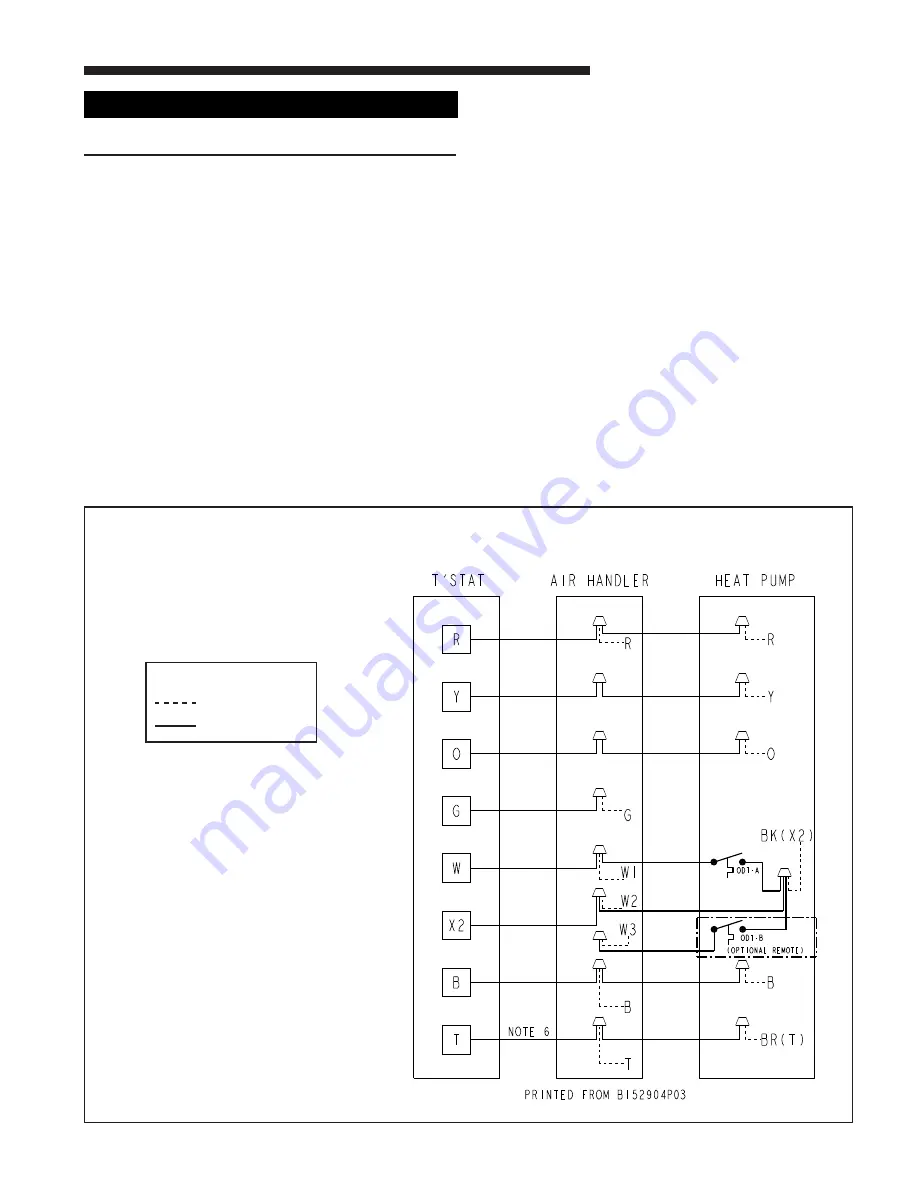

TYPICAL FIELD HOOK-UP DIAGRAM

LEGEND

FACTORY WIRING

FIELD WIRING

▲

WARNING

!

Do NOT connect 24 VAC to T1 (ODS-A) terminal. ODS-A

thermistor WILL BE BLOWN.

H. COMPRESSOR START UP

After all electrical wiring is complete, SET THE THERMO-

STAT SYSTEM SWITCH IN THE OFF POSITION SO

COMPRESSOR WILL NOT RUN, and apply power by

closing the system main disconnect switch. This will activate

the compressor sump heat (where used). Do not change the

Thermostat System Switch until power has been applied for

one (1) hour. Following this procedure will prevent potential

compressor overload trip at the initial start-up.

I. OPERATIONAL AND CHECKOUT

PROCEDURES

Final phases of this installation are the unit Operational

and Checkout Procedures which are found in this instruction

on page 8. To obtain proper performance, all units must be

operated and charge adjustments made in accordance with

procedures found in the Service Facts.

J. ELECTRIC HEATERS

Electric heaters, if used, are to be installed in the air han-

dling device according to the instructions accompanying the

air handler and the heaters.

K. OUTDOOR THERMOSTAT

An outdoor thermostat TAYSTAT250B may be field installed.

For data, see wiring diagram attached to unit and instruction

sheet packaged with outdoor thermostat.

L. SEACOAST SALT SHIELD

If installed within one mile of salt water, including seacoasts

and inland waterways, models without factory supplied

Seacoast Salt Shields require the addition of BAYSEAC001

(Seacoast Kit) at installation time. Please refer to Applica-

tion Guide SS-APB006-EN:

Trane - Seacoast Applications

and

Seacoast Corrosion Protection Bulletin

UN-SVB11A-EN.

Notes:

1. Be sure power supply agrees with equipment nameplate.

2. Power wiring and grounding of equipment must comply

with local codes.

3. Low Voltage wiring to be No. 18 AWG minimum conductor.

4. ODT-B Must be set lower than ODT-A.

5. If outdoor thermostats (ODT) are not used, connect WI to

W2 and W3.

6. N/A to programmable thermostat.