TRAK Machine Tools

Site Preparation Guide

TRAK DPMRX5

F16467-46 Rev 062518

Page 1 of 4

Before an Authorized Field Service Technician can perform the machine’s final checkout, the following requirements must be met:

The machine must be in position and placed on its rest pads

To offload the machine, a 6000 lb. forklift with 6’ extension is required.

The machine must be leveled (refer to installation and service manual).

The machine must be wired (refer to the installation and service manual).

The machine must have air hooked up if power drawbar is installed (see the

installation and service manual).

The machine must be cleaned. Remove all grease from the way surfaces.

Space & Weight

•

Floor area = 131.0625”x103”

•

Height = 102”

•

Footprint = 24”x48.4”

•

Net (approx.) Weight = 4400 lbs.

•

Shipping (approx.) Weight = 4600 lbs.

•

Pallet Size = 76”x76”, 8” thick

•

Allow clearance at the rear of the mill to open and work

on the electrical box.

•

A solid and level foundation to maintain approximately

4400 lbs plus the weight of the workpiece (maximum

total 6200 lbs) is required. Six leveling screws are

provided.

Electrical

•

Machine is only available in the 208 VAC configuration

(200 to 240V is acceptable). A separate 208V, 35 amps,

60 Hz, 3 phase circuit is required. For shops with 440

VAC, a step-down transformer to 208 VAC must be used.

The transformer must be sized to carry a load of 35

amps minimum.

•

Machine tool must be earth grounded.

Air (for optional Power Drawbar)

•

¼” NPT connection

•

Air pressure not to exceed 100 psi

•

17.5 SCFM or 2.5 CFM at 90 psi

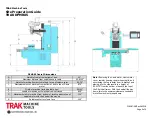

DPMRX5 Machine Footprints

A

Overall Width

131.0625”

B

Overall Length

103”

C

Bed Width

24”

D

Bed Width between leveling screws

21.7”

E

Distance between leveling screws

20.5”

F

Bed length

48.4”