57

Maintenance

5.

Repeat this for all three belts

6.

Make sure all belts are feeling the same in tension

8.13

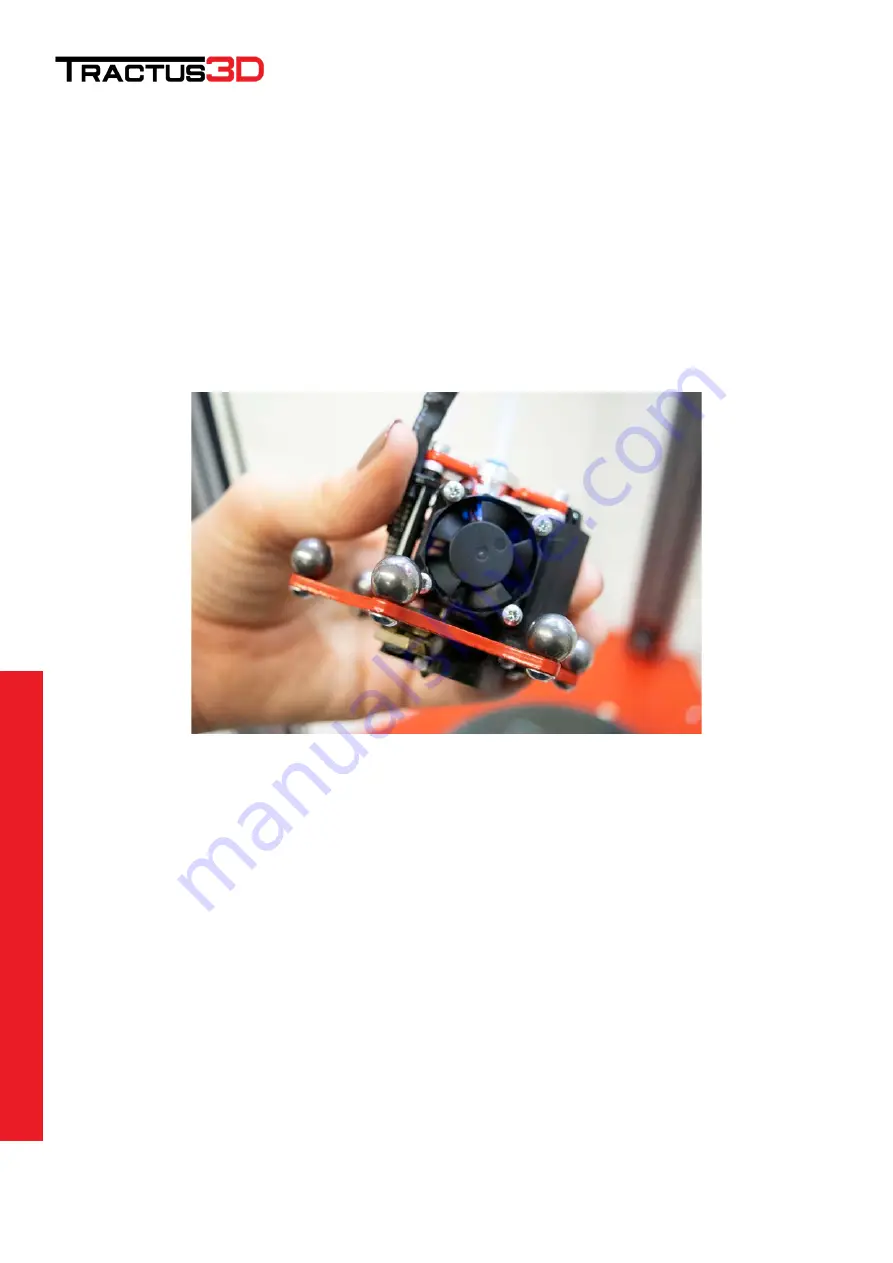

Check if print head fan is running after heating up

The small fan on the print head cools the print head during a print. This helps to prevent the heat from the nozzle

traveling too far upwards. The fan takes in air from the front of the print head and directs it towards the metal

cooling ribs of the print head. Sometimes the airflow causes thin strands of filament to be sucked into the fan

during a print. If strands accumulate in the fan, they can decrease the effective cooling and eventually obstruct

the fan and prevent it from spinning.

If you heat up the print head above 50 degrees Celsius the fan should start spinning. If it’s not spinning, please

don’t heat up the print head anymore and let it cool down. See if there are any obstructions in the fan. If there are

any, remove them with some tweezers.

If the fan is still not spinning and there is no obstruction found, the fan should be replaced. Contact our support

desk for more information.

8.14

Clean or replace the feeder/extruder motor

The feeder leads the filament to the print head. To ensure that the exact right amount of filament is extruded, the

feeder gear needs to turn turn smoothly.

Small filament particles might remain in the feeder after many hours of printing. We recommended to clean the

inside of the feeder after three months of use.

The following steps need to be performed

Heat up the print head and unload filament

(see chapter 7.2 Unload Filament)