Assembly Instructions | ILM Servo Kits

18

Edition 03/2021 EN

Reference design for ILM servo kits

6 REFERENCE DESIGN FOR ILM SERVO KITS

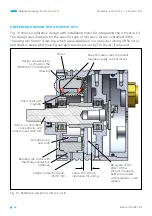

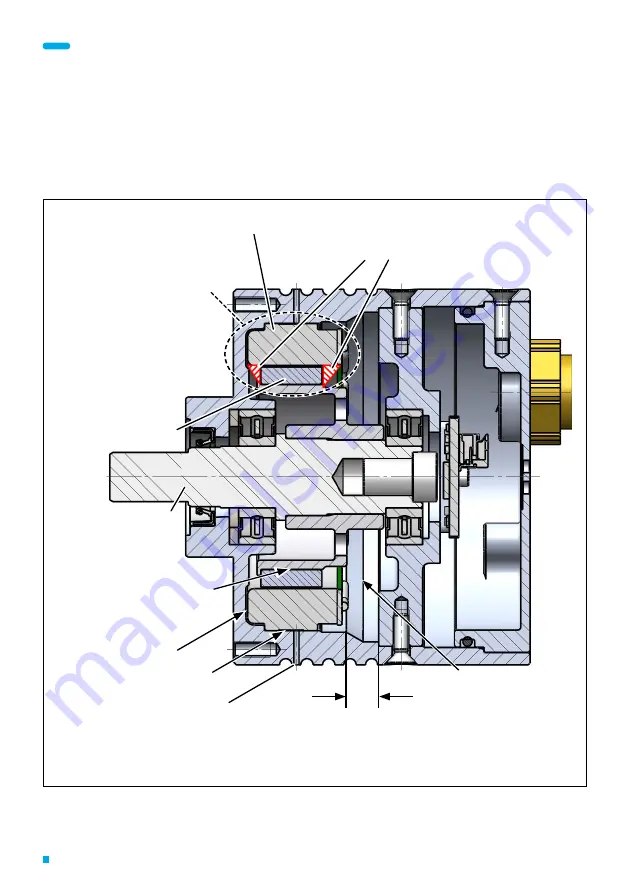

Fig. 10 shows a reference design with installation notes for integrating the ILM servo kit.

The design specifications for the specific type of ILM servo kit are contained in the

“Drawing ILM XXxXX” drawings which are available on our website. Joining of the rotor

and shaft or stator and housing can also be carried out by TQ-Drives, if required.

Stator

Rotor shell with

magnets

Hollow or solid shaft,

concentricity and

radial runout 0.02 mm

Bonding rotor

and shaft

Bonding the stator with

thermally-conductive

adhesive

Adhesive injection hole,

Ø 0.9 mm

Leave 8 to 10 mm

clearance for wiring

Be aware of the

effect of the

motor’s magnetic

field on encoders

with magnetic code

wheels.

Design specifications

as shown in the

"MEBS XX-YY Installation“

drawing

Keep this area clear to prevent

magnetic eddy current losses

Fig. 10: Reference design for ILM servo kits