P14821

P04002

125 mm

EM7639

P03829

P03828

EM--72

--

ENGINE MECHANICAL

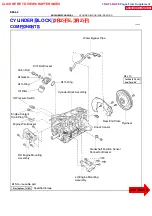

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

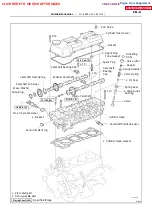

10. INSPECT PISTON RING GROOVE CLEARANCE

Using a thickness gauge, measure the clearance between new

piston ring and the wall of the piston ring groove.

Ring groove clearance:

No.1

2RZ -- FE: 0.020 -- 0.070 mm (0 .0008 -- 0.0028 in.)

3RZ--F: 0.030 -- 0.080 mm (0.0012 -- 0.0031 in.)

No.2

2RZ--FE: 0.030 -- 0.070 mm (0.0012 -- 0.0028 in.)

3RZ--F: 0.040 -- 0.080 mm (0.0016 -- 0.0031 in.)

If the clearance is not as specified, replace the piston.

11 . INSPECT PISTON RING END GAP

(a)

Insert the piston ring into the cylinder bore.

(b)

Using a piston, push the piston ring a little beyond the bot-

tom of the ring travel, 125 mm (4.92 in.) from the top of the

cylinder block.

(c)

Using a thickness gauge, measure the end gap.

Ring end gap:

No.1

2RZ--FE: 0.300 -- 0.400 mm (0.0118 -- 0.0157 in.)

3RZ--F: 0.300 -- 0.430 mm (0.0118 -- 0.0169 in.)

No.2

2RZ--FE: 0.400 -- 0.500 mm (0.0157 -- 0.0197 in.)

3RZ--F: 0.450 -- 0.600 mm (0.0177 -- 0.0236 in.)

If the end gap is not as specified, replace the piston ring. If the

end gap is not as specified, even with a new piston ring, rebore

all the 4 cylinders or replace the cylinder block.

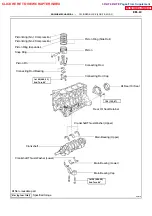

12. INSPECT PISTON PIN FIT

At 80 -- 90

˚

C (176 -- 194

˚

F), you should be able to push the pis-

ton pin into the piston pin hole with your thumb.

13. INSPECT CONNECTING ROD ALIGNMENT

Using a rod aligner and thickness gauge, check the connecting

rod alignment.

S

Check for out--of--alignment.

Maximum out--of--alignment:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If out--of--alignment is greater than maximum, replace the con-

necting rod assembly.

S

Check for twist

Maximum twist:

0.15 mm (0.0059 in. ) per 100 mm (3.94 in.)

If twist is greater than maximum, replace the connecting rod as-

sembly.

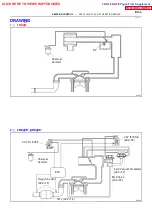

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE