Both intake and exhaust

Bushing bor diameter

Bushing size

mm (in.)

Use STD

Use O/S 0.05

11.000 -- 11.027

(0.4331 -- 0.4341)

11.050 -- 11.077

(0.4350 -- 0.4361)

Z15477

SST

8.2 -- 8.6 mm

Z15478

Sharp 6 mm Reamer

Z00054

44.5

˚

EM0181

Margin Thickness

--

ENGINE MECHANICAL

CYLINDER HEAD (2RZ--FE)

EM--45

(d)

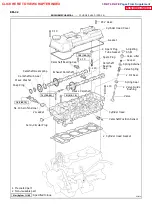

Select a new guide bushing (STD size or O/S 0.05).

If the bushing bore diameter of the cylinder head is greater than

11.027 mm (0.4341 in.), machine the bushing bore to these di-

mension:

11.050 -- 11.077 mm (0.4350 -- 0.4361 in.)

If the bushing bore diameter of the cylinder head is greater than

11.077 mm (0.4361 in.), replace the cylinder head.

(e)

Gradually heat the cylinder head to 80 -- 100

˚

C (176 --

212

˚

F).

(f)

Using SST and a hammer, tap in a new guide bushing to

where there 8.2 -- 8.6 mm (0.323 -- 0.339 in.) protruding

from the cylinder head.

SST 09201 -- 10000 (09201 -- 01060),

09950 -- 70010 (09951 -- 07150)

(g)

Using a sharp 6 mm reamer, ream the guide bushing to

obtain the standard specified clearance (See step 9 on

the previous page) between the guide bushing and valve

stem.

11 . INSPECT AND GRIND VALVES

(a)

Grind the valve enough to remove pits and carbon.

(b)

Check that the valve is ground to the correct valve face

angle.

Valve face angle:

44.5

˚

(c)

Check the valve head margin thickness.

Standard margin thickness:

1.0 mm (0.039 in.)

Minimum margin thickness:

0.5 mm (0.020 in.)

If the margin thickness is less than minimum, replace the valve.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE