– 23 –

C

C

B

A

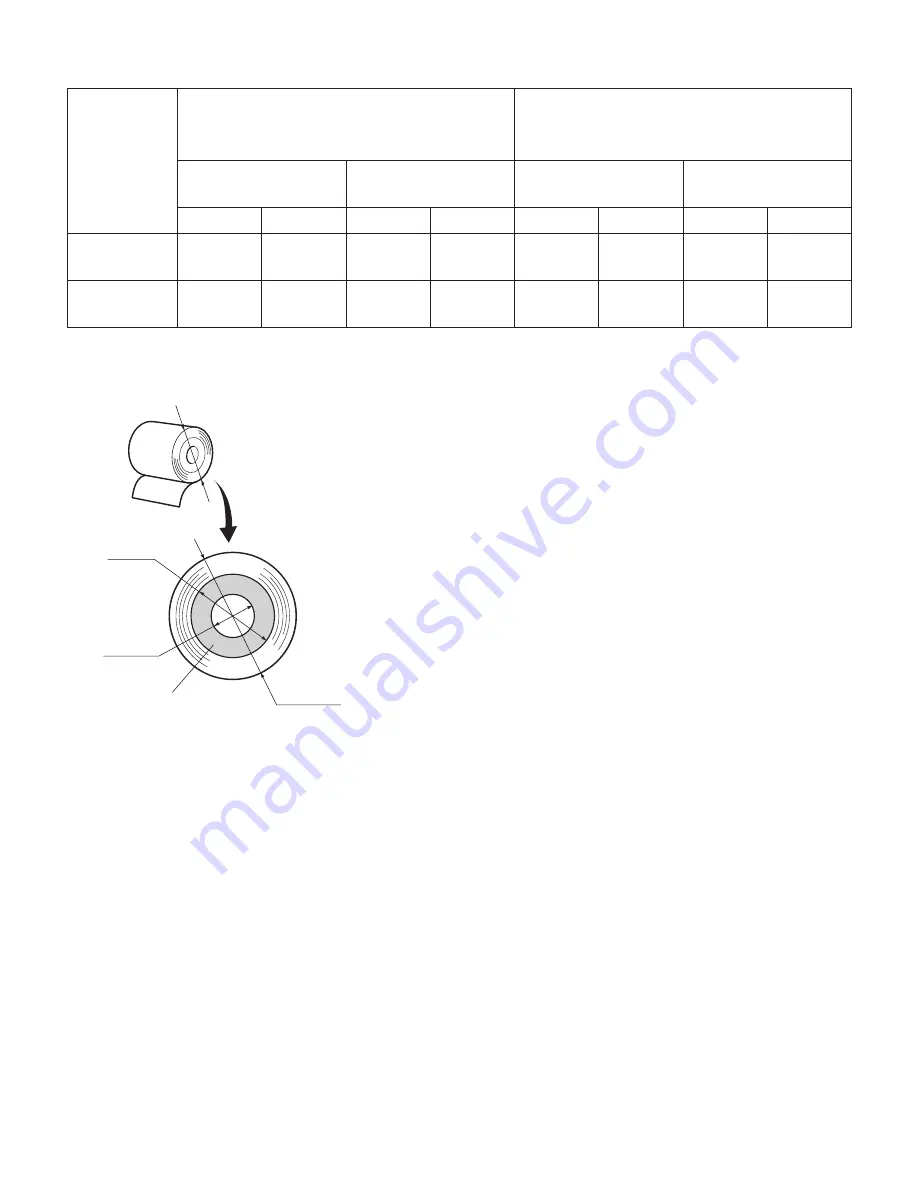

Paper roll core

Adjustment value according to the paper you are using

Paper Width

(µm)

Horizontal (standard) Layout

ø12 (A) inner diameter / ø18 (B) outer di-

ameter core roll paper

Vertical Layout or Wall-Mount

ø12 (A) inner diameter / ø18 (B) outer di-

ameter core roll paper

Detected diameter (C)

(mm)

Remaining paper

length (m)

Detected diameter (C)

(mm)

Remaining paper

length (m)

Level 1

Level 2

Level 1

Level 2

Level 1

Level 2

Level 1

Level 2

65

Approx.

ø23

Approx.

ø29

Approx.

2.5

Approx.

6.3

Approx.

ø23

Approx.

ø29

Approx.

2.5

Approx.

6.3

85

Approx.

ø23

Approx.

ø29

Approx.

1.9

Approx.

4.8

Approx.

ø23

Approx.

ø29

Approx.

1.9

Approx.

4.8

Notes:

1) The adjuster is factory-set at level 1.

2) The detected diameter and remained paper length given

in the table are calculated values, and there are some

variances depending on the rolled state of the paper,

the actual mechanism, or the printing pattern.

3) If thick paper is used (paper thickness between

80 µm and 85 µm), the paper roll may loosen and

cause variances in the detected values. Therefore,

setting the adjuster to Level 2 is recommended.

Содержание PR-TB-650-N

Страница 1: ...THERMAL PRINTER PR TB 650 N Hardware Manual...

Страница 10: ...3 3...

Страница 49: ......