ELECTRICAL ADJUSTMENTS

4. PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

1.

2.

3.

Turn the unit on and let it warm up for at least 30

minutes before performing the following adjustments.

Place the CRT surface facing east or west to reduce the

terrestrial magnetism.

Turn ON the unit and demagnetize with a Degauss Coil.

4-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

1.

2.

3.

4.

5.

6.

7.

8.

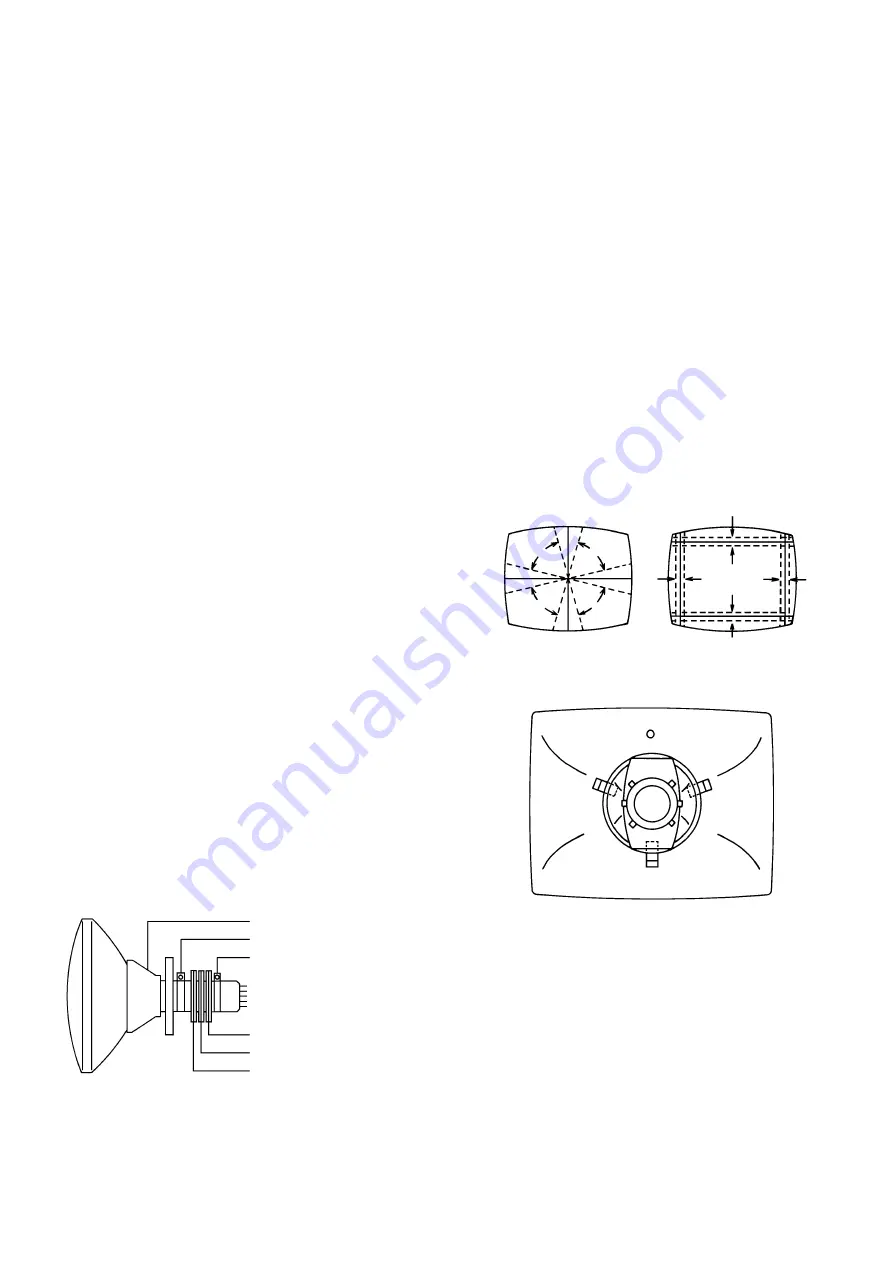

Tighten the screw for the magnet. Refer to the adjusted

CRT for the position. (Refer to Fig. 4-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

Receive the green raster pattern from the color bar

generator.

Slide the deflection yoke until it touches the funnel side

of the CRT.

Adjust center of screen to green, with red and blue on

the sides, using the pair of purity magnets.

Switch the color bar generator from the green raster

pattern to the crosshatch pattern.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of 4

pole magnets.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

Adjust the crosshatch pattern to change to white by

repeating steps 6 and 7.

4-2: PURITY

NOTE

Adjust after performing adjustments in section 4-1.

1.

2.

3.

4.

5.

Receive the green raster pattern from color bar

generator.

Adjust the pair of purity magnets to center the color on

the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole screen

is green.

Confirm red and blue colors.

Adjust the slant of the deflection yoke while watching

the screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

6 POLE MAGNETS

4 POLE MAGNETS

PURITY MAGNETS

Fig. 4-1

4-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 4-2.

1.

2.

3.

Receive the crosshatch pattern from the color bar

generator.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of 4

pole magnets.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

4-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 4-3.

1.

2.

Adjust the differences around the screen by moving the

deflection yoke upward/downward and right/left.

(Refer to Fig. 4-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 4-2-b)

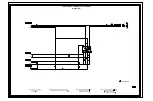

R G B

R

G

B

R G B

R

G

B

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

Fig. 4-2-a

WEDGE

WEDGE

WEDGE

WEDGE POSITION

Fig. 4-2-b