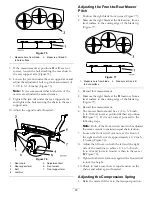

3. Remove the dust cap from caster and tighten lock

nut (Figure 53).

4. Tighten the locknut until the spring washers are flat

and then back off a 1/4 turn to properly set the

pre-load on the bearings (Figure 53).

Important:

Make sure spring washers are

installed correctly as shown in Figure 53.

5. Install the dust cap (Figure 53).

Figure 53

1.

Spring Washers

3.

Dust Cap

2.

Lock Nut

Servicing the Gear Box

Checking the Gear Box Oil Level

Service Interval:

Every 100 hours

Yearly

Use SAE 75W–90 Synthetic Gear Lube.

1. Park the machine on a level surface.

2. Disengage the PTO, move the motion control levers

to the neutral locked position and set the parking

brake.

3. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

4. Loosen the lug nuts on the right rear wheel.

5. Raise rear of the machine so the right rear wheel is

off the ground and support the machine with jack

stands.

6. Remove the right rear wheel from the machine.

7. Locate the hole in the frame and remove the side

plug in the gear box. (Figure 54).

8. The oil needs be up to the opening of the gear box

hole.

9. Add oil if needed to bring it to the correct level.

Figure 54

1.

Right rear wheel

3.

Jack stand

2.

Lug nuts

4.

Hole in the side of frame

to access the side plug

Changing the Gear Box Oil

Service Interval:

After the first 100 hours

Contact an Authorized Service Dealer to change the

gear box oil.

41

Содержание Z589 Z Master

Страница 6: ...Slope Chart 6 ...

Страница 8: ...98 5954 105 7798 107 1613 107 1857 107 1860 107 1861 107 1864 8 ...

Страница 9: ...107 2102 107 2112 107 2114 107 2449 108 5981 110 2067 9 ...

Страница 61: ...Schematics Wire Diagram Rev A 61 ...

Страница 62: ...Notes 62 ...