Storage

Storing the Machine

WARNING

•

Gasoline fumes are highly flammable, explosive,

and dangerous if inhaled. If you store the

machine in an area with an open flame, the

gasoline fumes may ignite and cause an

explosion.

•

Do not store the machine in a house (living

area), basement, or any other area where ignition

sources may be present, such as hot water and

space heaters, clothes dryers, furnaces, and

other like appliances.

•

Do not tip the machine either forward or

backward with fuel in the fuel tank; otherwise,

fuel may leak out of the machine.

•

Do not store the machine with its handle tipped

down onto the ground, because oil will leak into

the engine cylinder and onto the ground, and

the machine will not start or run.

1.

On the last refueling of the season, add fuel stabilizer

to fresh fuel as directed by the engine manufacturer.

2.

Run the engine for 10 minutes to distribute the

conditioned fuel through the fuel system.

3.

While the engine is still warm, change the engine oil.

Refer to Changing the Engine Oil.

4.

Drain the fuel from the tank and carburetor by

performing the following steps:

A.

Unscrew, but do not remove, the small screw on

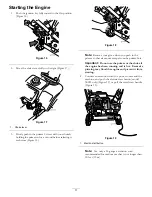

the side of the carburetor fuel bowl (Figure 31)

until the fuel begins to drain from the carburetor.

Drain the fuel into an approved fuel container.

Important:

Do not remove the carburetor

bowl bolt on the bottom of the carburetor.

Figure 31

1.

Carburetur bowl bolt—do

not remove

2.

Small screw on carburetor

B.

Wait for a few minutes until the fuel has drained,

then install the fuel cap and tighten the small

screw on the carburetor.

Note:

Use a handheld Phillips screwdriver.

Overtightening can cause the small screw to strip.

5.

Dispose of unused fuel properly. Recycle it according

to local codes, or use it in your automobile.

6.

Remove the spark plug.

7.

Squirt 2 teaspoons of oil into the spark plug hole.

8.

Install the spark plug by hand and then torque it to

20–22 ft-lb (27–30 N-m).

9.

With the ignition key in the Off position, pull the recoil

starter slowly to distribute the oil on the inside of the

cylinder.

10.

Disconnect the ignition key from the lanyard and store

the ignition key in a safe place.

11.

Clean the machine.

12.

Touch up chipped surfaces with paint available from an

Authorized Service Dealer. Sand affected areas before

painting, and use a rust preventative to prevent the

metal parts from rusting.

13.

Tighten any loose fasteners. Repair or replace any

damaged parts.

14.

Cover the machine and store it in a clean, dry place

out of the reach of children. Allow the engine to cool

before storing it in any enclosure.

17

Содержание Powerlite 38273

Страница 18: ...Notes 18...