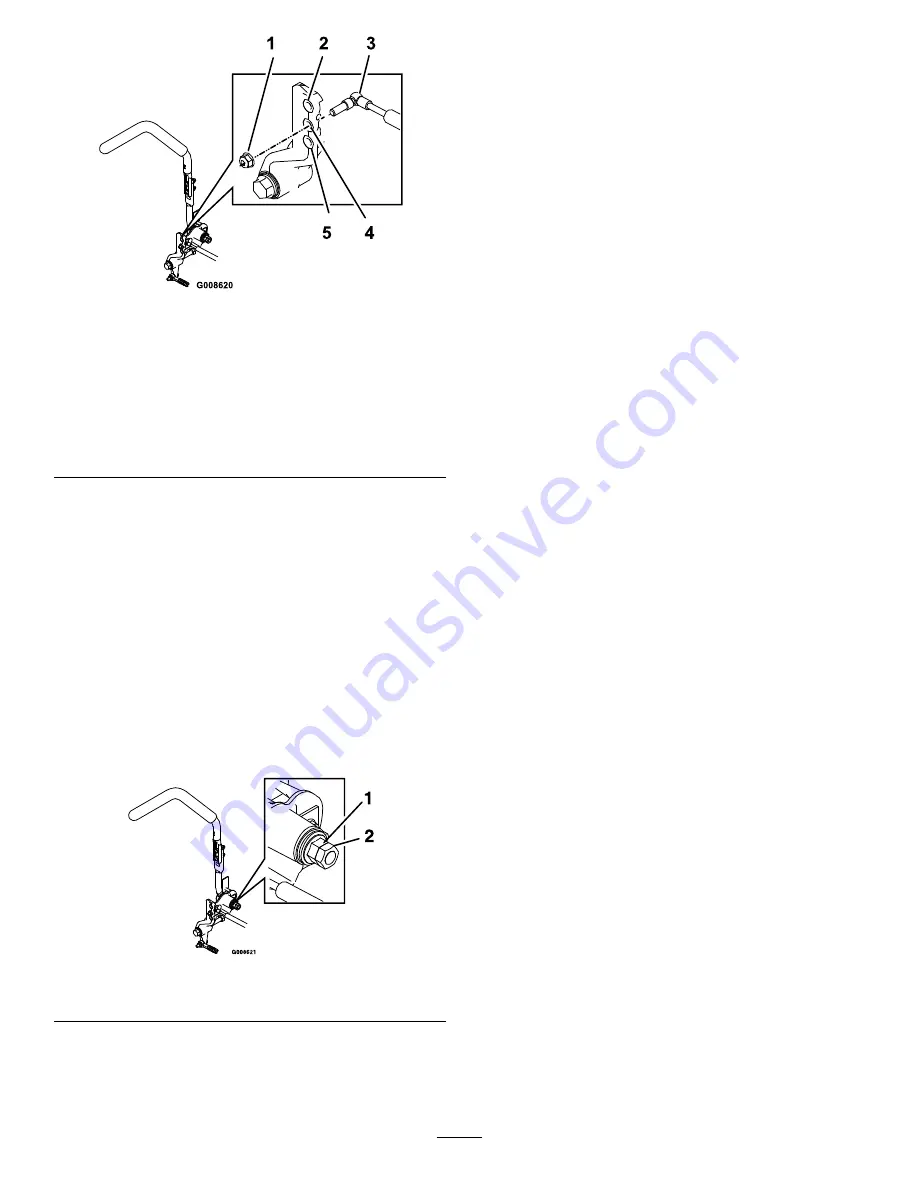

Figure 83

RH Motion Control Shown

1.

Torque the lock nut to 200 in-lb (16.7 ft-lb). Bolt must

protrude past end of locknut after torque.

2.

Least resistance (softest feel)

3.

Damper

4.

Medium resistance (medium feel)

5.

Most resistance (firmest feel)

Adjusting the Motion Control

Neutral Lock Pivot

The flanged nut can be adjusted to obtain a more desired

motion control lever resistance when moving it to the neutral

lock position. See Figure 84 for adjustment options.

1.

Loosen the jam nut.

2.

Tighten or loosen the flanged nut to the desired feel.

For more resistance, tighten the flanged nut.

For less resistance, loosen the flanged nut

3.

Tighten jam nut.

Figure 84

1.

Flanged nut

2.

Jam nut

Hydraulic System

Maintenance

Servicing the Hydraulic

System

Hydraulic Oil Type:

Toro

®

HYPR-OIL

™

500 hydraulic oil

or Mobil

®

1 15W-50.

Important:

Use oil specified. Other fluids could cause

system damage.

Each Hydraulic System Oil Capacity:

52 ounces (1.5 l) per

side with filter change

Checking the Hydraulic Oil

Service Interval:

Every 50 hours—Check the hydraulic oil

level.

1.

Position the machine on a level surface.

2.

Disengage the PTO, move the motion control levers to

the neutral locked position and set the parking brake.

3.

Stop the engine, remove the key, and wait for all moving

parts to stop before leaving the operating position.

4.

Allow the engine and hydraulic system to cool for ten

minutes.

Note:

The oil level on the dipstick will be incorrect

when the oil is checked and the unit is hot.

5.

Move the seat forward.

6.

Clean the area around the dipsticks of hydraulic system

reservoirs (Figure 85).

7.

Remove one dipstick from the hydraulic reservoir

(Figure 85).

8.

Wipe the dipstick off and thread the dipstick into the

reservoir.

9.

Remove the dipstick and look at the end (Figure 85).

If the oil level is at the add mark , slowly pour only

enough oil into the hydraulic reservoir to raise the level

to the full or

H

line.

Important:

Do not overfill the hydraulic units

with oil as damage may occur. Do not run the

machine with the oil below the add mark.

10.

Install the dipstick.

11.

Repeat procedure for the opposite dipstick.

53

Содержание 74901 Z Master 5000

Страница 28: ...Figure 40 1 Trailer 3 Not greater than 15 degrees 2 Full width ramp 4 Full width ramp side view 28 ...

Страница 66: ...Schematics Wire Diagram Rev A 66 ...

Страница 67: ...Notes 67 ...