•

If the engine slows down under a load or the wheels

slip, shift the machine into a lower gear.

•

If the front of the machine rides up, shift the

machine into a lower gear. If the front continues to

ride up, lift up on the handles.

•

The pivoting scraper on the machine is not

recommended for use on gravel surfaces.

But

if you must use the machine on a gravel surface,

adjust the skids further down to prevent the pivoting

scraper from picking up rocks.

Maintenance

Note:

Determine the left and right sides of the machine from the normal operating position.

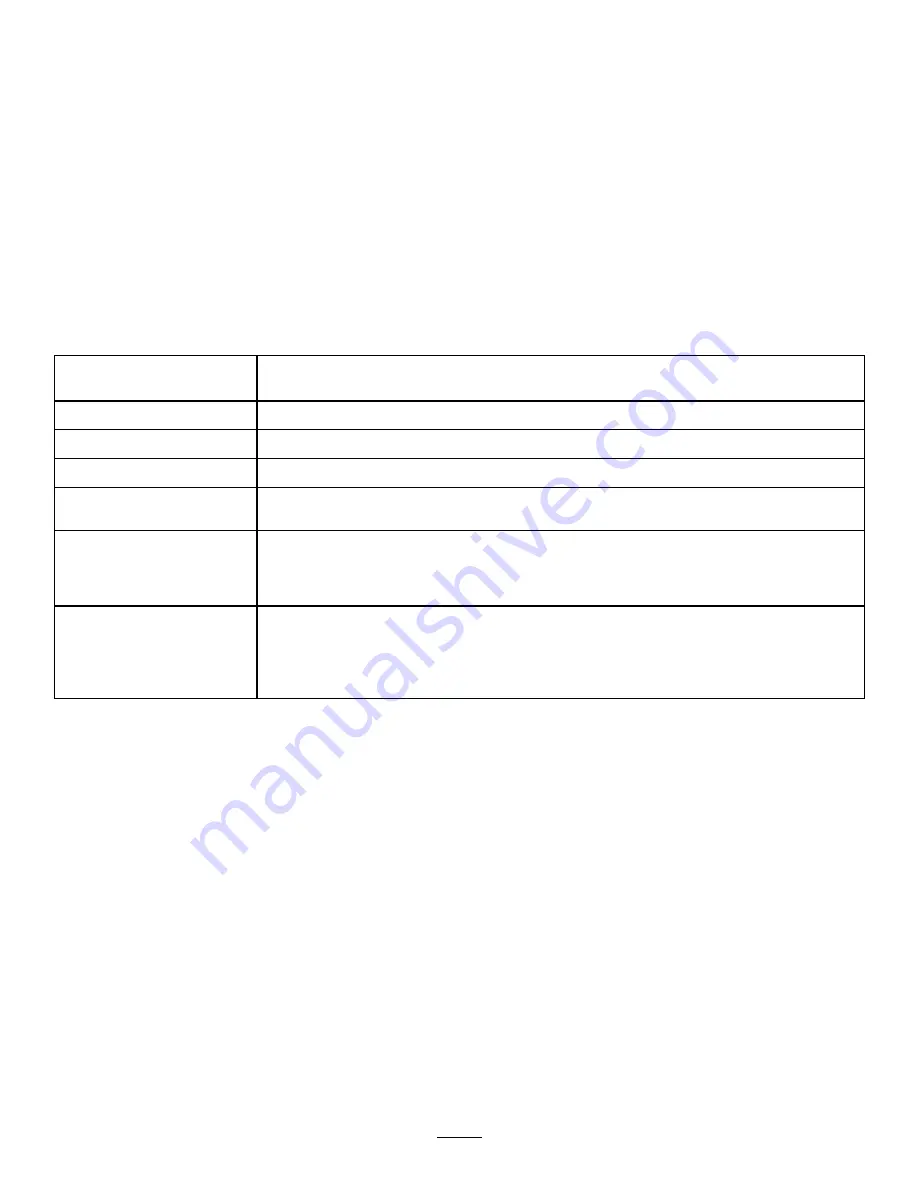

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first 2 hours

• Inspect the traction cable and adjust it if necessary.

After the first 5 hours

• Change the engine oil.

Before each use or daily

• Check the engine oil level and add oil if necessary.

Every 50 hours

• Change the engine oil. Change the engine oil every 25 operating hours when

operating the engine under a heavy load.

Yearly

• Check the skids and the scraper and adjust them if necessary.

• Check the skids and adjust them if necessary.

• Inspect the traction cable and adjust or replace it if necessary.

• Check the auger gearbox oil and add oil if necessary.

Yearly or before storage

• Check the air pressure in the tires and inflate them to 17–20 psi (116–137 kPa).

• Drain the gasoline and run the engine to dry out the fuel tank and the carburetor at

the end of the season.

• Have an Authorized Service Dealer inspect and replace the traction drive belt and/or

the auger/impeller drive belt, if necessary.

Important:

You can find more information about maintaining and servicing your machine at

www.Toro.com.

Important:

Refer to your engine operator’s manual for additional maintenance procedures. For engine

adjustments, repairs, or warranty service not covered in this manual, contact an Authorized Briggs

& Stratton Servicing Dealer.

20

Содержание 38597

Страница 29: ...Notes 29 ...

Страница 30: ...Notes 30 ...