5

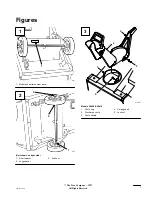

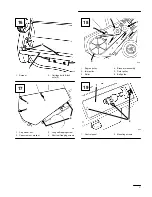

Install Discharge Chute And

Chute Handle (Fig. 3)

Models 38409 & 38414

1.

Place chute handle over chute ring.

2.

Insert discharge chute between chute ring and

chute handle. Align holes.

3.

Secure back of chute and handle to center hole in

chute ring with a carriage bolt and lock nut.

Position nut on outside of chute.

Note:

Chute ring may be rotated to ease

assembly of discharge chute.

4.

Secure chute and handle to remaining holes in

chute ring and tighten all nuts SECURELY.

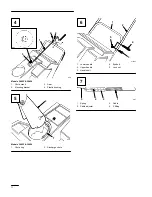

Install Chute Crank (Fig. 4)

Models 38422 & 38424

1.

Insert flattened end of chute crank through hole

in shroud while aligning mounting bracket with

holes in lower handle. Slowly rotate crank until

flattened end fits into hidden gear opening and

chute ring turns with crank. Make sure plastic

bushing is fully inserted into hole in mounting

bracket, then secure mounting bracket to handle

with (2) capscrews and locknuts.

Install Discharge Chute (Fig. 5)

Models 38422 & 38424

1.

Set discharge chute onto chute ring. Align hole

in back of chute with center hole in ring and

install a carriage bolt and sems locknut. Position

nut on outside of chute.

Note:

Chute ring may be rotated to ease

assembly of discharge chute.

2.

Secure chute to remaining holes in chute ring

and tighten all nuts SECURELY.

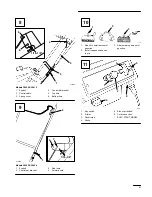

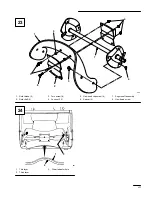

Install Handle (Fig. 6)

1.

Remove tie securing control cable to lower

handle.

2.

Position upper handle so that control bar is on

top of handle, not underneath it.

3.

Secure upper and lower handle in place with (3)

handle bolts, (1) eyebolt, and (4) lock nuts. Use

eyebolt to mount upper left side of handle.

Eyebolt must be positioned perpendicular to

handle when tightened.

Install Control Cable

Models 38409 & 38414

1.

Route control cable through eyebolt on left side

of snowthrower.

2.

Hook spring to round hole at end of cable

adjuster (Fig. 7).

3.

Route cable through elongated hole in cable

adjuster. Insert Z fitting on end of cable into 3rd

hole on cable adjuster (Fig. 7).

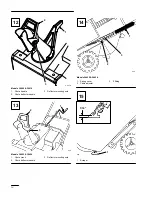

4.

Slide spring cover over spring and cable adjuster.

Push spring end through hole at end of spring

cover.

5.

Hook spring into top hole of control bar bracket

(Fig. 8).

6.

Move control bar back toward handle until slack

in cable is removed. The gap between the control

bar bracket and handle should be approximately

1/16”-1/8”. See insert, Figure 8. If an adjustment

is required, refer to Adjusting Control Bar,

page 9.

Note:

The control cable must always have

slack in it when in the disengaged

position.

Содержание 38409

Страница 8: ...vi 1 628 1 Spark plug wire 0 032 0 81 mm 110 1 1 Wear indicator hole 20 21 22 ...

Страница 27: ......