•

Pull the handle to broadcast granular product

from the left side of the impeller.

•

Push the handle to block granular product

from broadcasting at the left side of the

impeller.

3.

Rotate the handle of the deflector control

clockwise to lock the control (

Adjusting the Diffuser Control

Use the diffuser control to adjust the spread granular

product heavier to the left, consistent in the middle, or

heavier to the right.

1.

Rotate the handle of the diffuser control

counterclockwise to unlock the control (

2.

Adjust the diffuser control as follows:

•

Pull the handle to broadcast more granular

product from the right side of the impeller.

•

Center the handle to balance the broadcast

granular product evenly.

•

Push the handle to broadcast more granular

product from the left side of the impeller.

3.

Rotate the handle of the diffuser control

clockwise to lock the control (

Before Operating the Spreader

Before you start using the spreader, calibrate the

spreader for the material that you will disperse; refer

to

Calibrating the Spreader (page 26)

.

Important:

Prior to filling the hopper, verify that

you have set the proper spreader-application rate.

Calibrating the Spreader

Calibrate the spreader each time you change granular

materials. The spreader broadcasts material in a

pattern 1 to 7.6 m (3 to 25 ft) wide depending on the

material particle size, volume/density, impeller-motor

speed, rate of travel, and wind conditions.

Use the

Spreading Charts (page 30)

along with

information from

Determining the Distribution Pattern

(page 27)

,

Determining the Effective Spreading Width

(page 27)

, and

Calculating the Application Rate (page

when calibrating the spreader.

Preparing the Test Site and Machine

Operator supplied equipment:

15 shallow collection

pans and 15 graduated measuring cylinders

Note:

The most accurate method to measure

the distribution uses shallow collection pans and

graduated measuring cylinders. In the example below,

the 15 shallow collection pans approximately 30 cm

(12 inches) wide, 91 cm (36 inches) long, and 5 cm

(2 inches) tall.

1.

Place one pan in the center of the drive path.

Arrange the next two pans, one on each side,

far enough apart to allow adequate room for the

drive tires of the machine to pass around the

center pan.

2.

Place the remaining pans in a straight line as

shown in

or

.

•

For larger granule materials:

Space 6 additional pans, on each side, 12

inches (30 cm) apart (

).

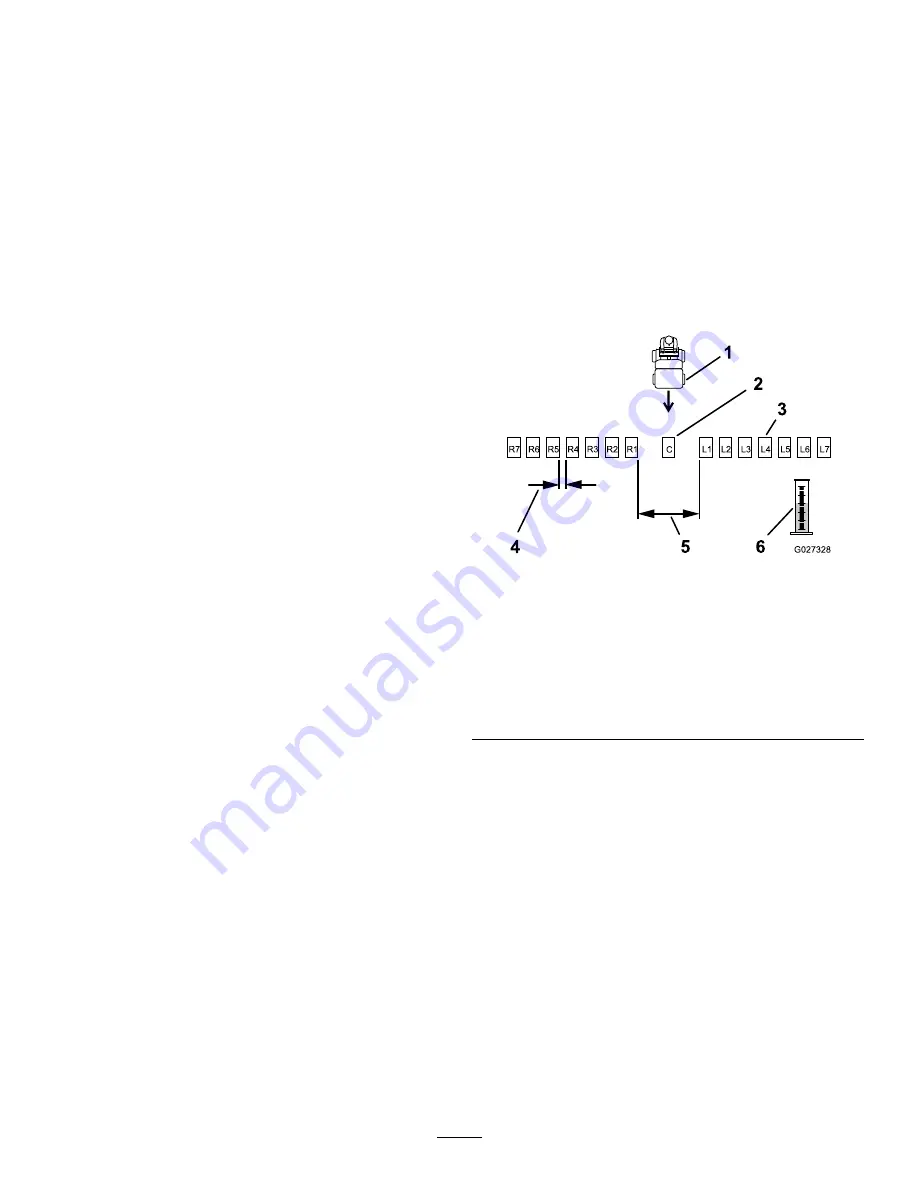

g027328

Figure 20

Pan spacing for larger granule materials

1.

Spreader moving toward

pans

4.

L1 and R1 collection pan

gap (spread apart to allow

machine to pass through)

2.

Center pan

5.

30 cm (12 inch) gap

3.

Collection pans (gap

between each)

6.

Graduated measuring

cylinder

•

For small granule materials:

Place 6 additional pans, on each side, with

no gap in between each pan (

26