10

TOPEX.PL

when the tool is not used for a long period of time (night, weekend etc.) it must be additionally lubricated. The tool must

operate for approximately 30 seconds for the oil to distribute evenly on the tool parts. Keep the tool in clean and dry place.

with the lubricator use appropriate oil designed for air tools lubrication. Substitute oils may damage rubber seals and other

rubber elements of the tool. Lubricator must allow for use of small or variable air flow. fill the lubricator up to appropriate

level.

imPOrTAnT!!!

If there is no filter-regulator-lubricator unit in the air circuit, lubricate air tools at least once a day or after two hours of operation.

depending on the working environment, put two to six drops of oil through male fitting in the tool body.

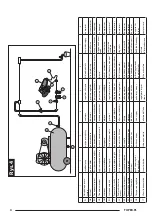

Parts of the system (ref. fig. 4).

Air tool, quick coupler, pneumatic hose, lubricator, pressure regulator, filter/water trap, cut-off valve, air compressor.

OPErATinG ThE TOOL

cAUTiOn

: Before using the tool you must read, understand and follow safety rules.

Use only discs with diameter matching dimensions of sander guard and spindle

»

connect the sander to compressed air supply as described in section “Air supply”

»

dO NOT ALLOw the sander to operate for a long time without load, that would reduce the tool life.

»

mAinTEnAncE

cAUTiOn

: disconnect the tool from air supply before replacing accessories or carrying out maintenance or service actions.

Replace damaged parts. Use only original parts. Parts unauthorized by the manufacturer may be dangerous and using them

voids the warranty.

Lubricate the sander daily with few drops of oil designed for use with air tools. Bring the oil into air inlet connector.

clean the tool after use.

Loss of power or faulty operation may be caused by:

overloaded air supply,

»

moisture or obstacle in the air hose,

»

inappropriate dimension or type of hose connectors.

»

To correct the tool operation check air supply circuit and follow instructions contained in the section “Air supply”.

TrOUbLEshOOTinG

The below table lists most common problems and their solutions. Read the table and follow notes contained therein.

cAUTiOn

: If any of the symptoms listed below appears during the tool operation, switch off the tool immediately.

Only qualified persons or authorized service centres can carry out repairs or oil change in the tool.

disconnect the tool from air supply before carrying out repair or tool adjustments.

After replacement of air motor part and before assembling the tool lubricate it with oil designed for air tools.

PrObLEm

POssibLE cAUsEs

sOLUTiOns

Tool operates at normal speed but

slows down under load.

motor parts worn out.

Replace worn parts.

Tool operates at small speed.

Small air flow from exhaust.

- parts of motor or air flow in the

hose blocked by dirt particles

Ensure air inlet is not blocked.

Put oil designed for use with air tools into air inlet

connector as described in the manual.

Switch on the tool for a while, depending on needs.

Repeat the procedure when needed. Return the tool

to service centre if the fault does not disappear.

Содержание 74L214

Страница 2: ......

Страница 12: ...12 TOPEX PL 10 11 12 6 3 6 3 8 8 4 30 30 2 6 4...

Страница 13: ...13 TOPEX PL...

Страница 14: ...14 TOPEX PL 74L214 25 10 000 140 5 6 3 1 4 1 3 pr EN15744 1999 EN08662 13 1997 1 2 3 4 5 6 7 8 9 10 11 12...

Страница 15: ...15 TOPEX PL 6 3 6 3 8 8 4 30 30 4...

Страница 16: ...16 TOPEX PL...

Страница 36: ...36 TOPEX PL 4 30 30 2 6 4...

Страница 37: ...37 TOPEX PL...