7

order to maintain proper stability.

The installation proceeds are as follows:

1.

Dig a hole for a concrete pad which should

be approximately 40 x 24 x 30cm (15.7”x 9.4”x

11.8”). It may protrude 10 cm (4”) above ground

and 20 cm (7.9”) in depth underground.

Increase the pad height if necessary to protect

the system from flooding, heavy snow etc.

2.

Prepare one or more conduits for the

electrical cables before pour concrete.

Remember that cable conduits have to pass

through the hole in opener base.

3.

Pour concrete and before it starts to harden,

check that it is parallel to the gate leaf and

perfectly level.

4.

Make sure the position of Expansion Tubes

was placed according to the position of

mounting holes on the opener base.

5.

Mount the opener to the concrete Pad. It's only temporary installation. Further adjustment will be

required when install the rack.

Manual Operation

You can open the gate by manual when power failure. And the opener should be put in the manual

(emergency release) position before fitting the rack, installing the opener and limit switch. The process is as

follows:

Insert the Release Key and turn it in clockwise 90°, then pull the release handle in clockwise 90° to

disengage the clutch between the gear shaft and motor. Now the opener is in the manual operation.

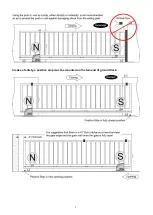

Fit the Plastic Rack Reinforced with Steel

1. Start with gate in closed position

2. Prepare the plastic rack (you can order extra rack from dealer if necessary).

3. Put one end of rack section on the gear of opener as a temporary support.

Make rack level and mark the rack’s mounting holes

(four holes for light duty or six holes for heavy duty)

on the gate.

4. Fit the rack by self-threading screws. This kind of plastic rack is quieter and allows height adjustments to

be made even after it has been fixed. Please keep 1.0mm space between the rack and the gear to avoid the

weight of the gate effect on the opener.