15

6. CHANGING SOCKETS

WARNING

●

Release ejector pin by pulling ejector lever

before changing sockets.

Accidental ejector pin release invites blindness or

injury.

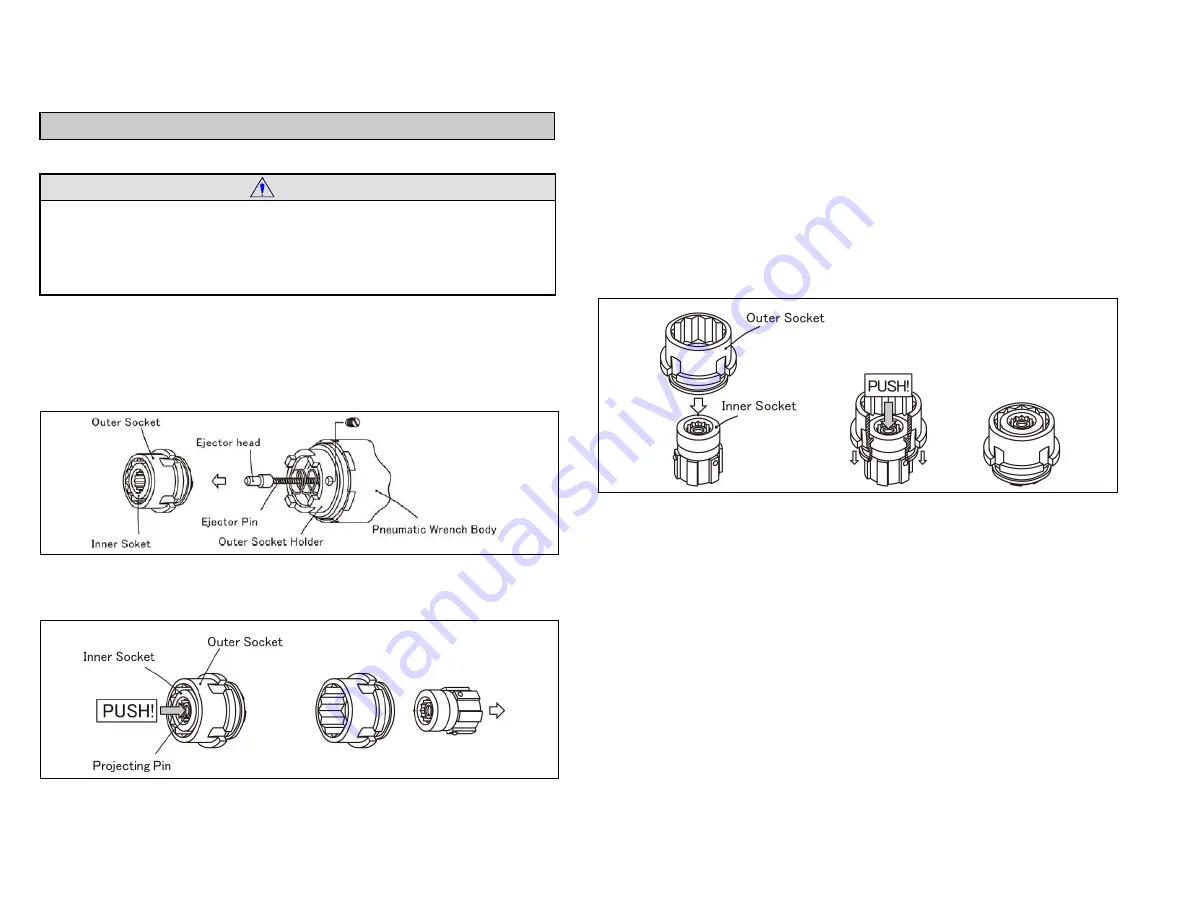

(1) Remove inner & outer socket assembly from pneumatic

wrench by unscrewing set screws (Figure 4). Do not remove

set screws completely from outer socket holder.

Figure 4

(2) Remove inner socket from outer socket by pushing

projecting pin using screwdriver or TC bolt (Figure 5).

Figure 5

●

Projecting pin is a doughnut-shaped pin in the inner

socket.

16

(3) Select adequate inner & outer socket assembly of the

bolts being tightened.

i.e. Use TONE genuine 5/8

”

inner & outer socket assembly

for tightening

5/8

”

TC bolt/nut assembly

(4) Place the inner socket vertically then slide the outer

socket over the inner socket. Push projecting pin down

using screwdriver or pintail of the TC bolt and inner &

outer socket will properly assembled (Figure 6).

Figure 6

(5) Set inner & outer socket assembly to pneumatic wrench

body and completely remove the gap between socket assembly

and wrench body.

The gap can be removed by turning & pushing down

screwdriver or TC bolt into the inner socket.

Fasten the set screws only after gap is completely removed.

Содержание PW200

Страница 12: ...21 MEMO MEMO 22 ...