172-65288MA-02 (SW1U-A/SW1U-B) 6 Feb 2019

5

Checking the Piping

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Check to make sure that the pipes to be connected to the trap have been installed

properly.

1. Is the pipe diameter suitable?

2. Is the piping where the trap is to be installed horizontal?

3. Has sufficient space been secured for maintenance?

4. Have isolation valves been installed at the inlet and outlet? If the outlet is subject

to back pressure, has a check valve been installed?

5. Has a bypass line been installed properly?

6. Is the inlet pipe as short as possible, with as few bends as possible, and installed

so the liquid will flow naturally down into the trap?

Operation

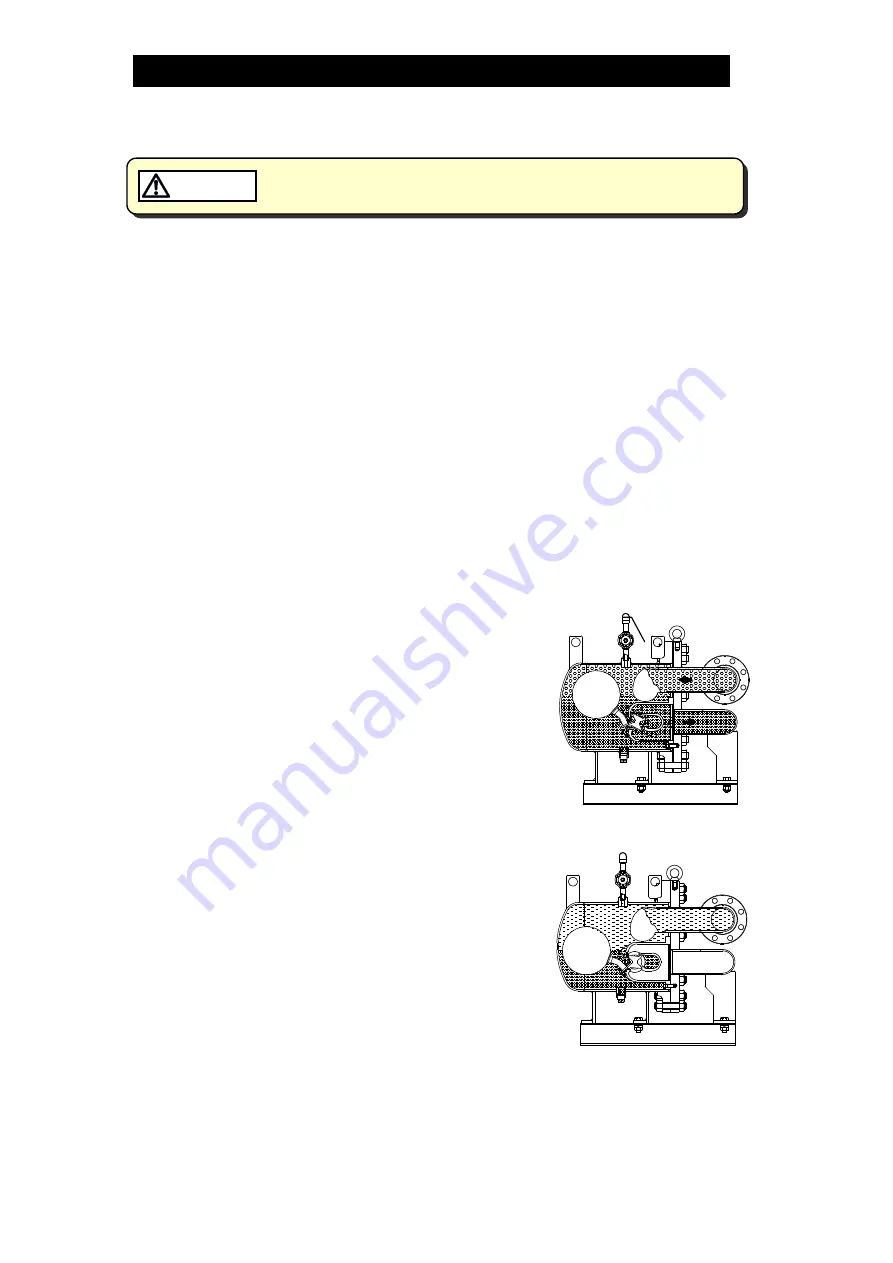

Principles of condensate discharge:

At start-up, open the bypass valve to remove any initial

condensate or air at 100

°

C (212

°

F) or less.

(This step must be performed in order to ensure

smooth start-up.)

Air binding occurs when the inflow of steam is

accompanied by the inflow of air during normal

operation. Whenever air binding occurs, it can be

released by opening the bellows sealed valve to

discharge the air.

After air is discharged, the bellows sealed valve must

be closed.

As condensate flows into the trap, the rising

condensate level causes the float to rise due to

buoyancy, automatically opening the valve and

allowing condensate to be continuously discharged.

When this occurs, the opening size of the valve varies

depending on the condensate flow rate.

As the condensate is discharged, the condensate level

falls, causing the float to fall, thereby automatically

closing the valve.

The valve remains closed as long as no condensate

enters the trap.

Bellows Sealed

Valve