172-65191MA-03 (RT3A) 28 Apr 2009

4

Checking the Piping

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Check to make sure that the pipes to be connected to the trap have been installed

properly.

1. Is the pipe diameter suitable?

2. Has sufficient space been secured for maintenance?

3. Have isolation valves been installed at the inlet and outlet?

If the outlet is subject to back pressure, has a check valve (TLV-CK) been

installed?

4. Is the inlet pipe as short as possible, with as few bends as possible, and installed

so the liquid will flow naturally down into the trap?

Operation

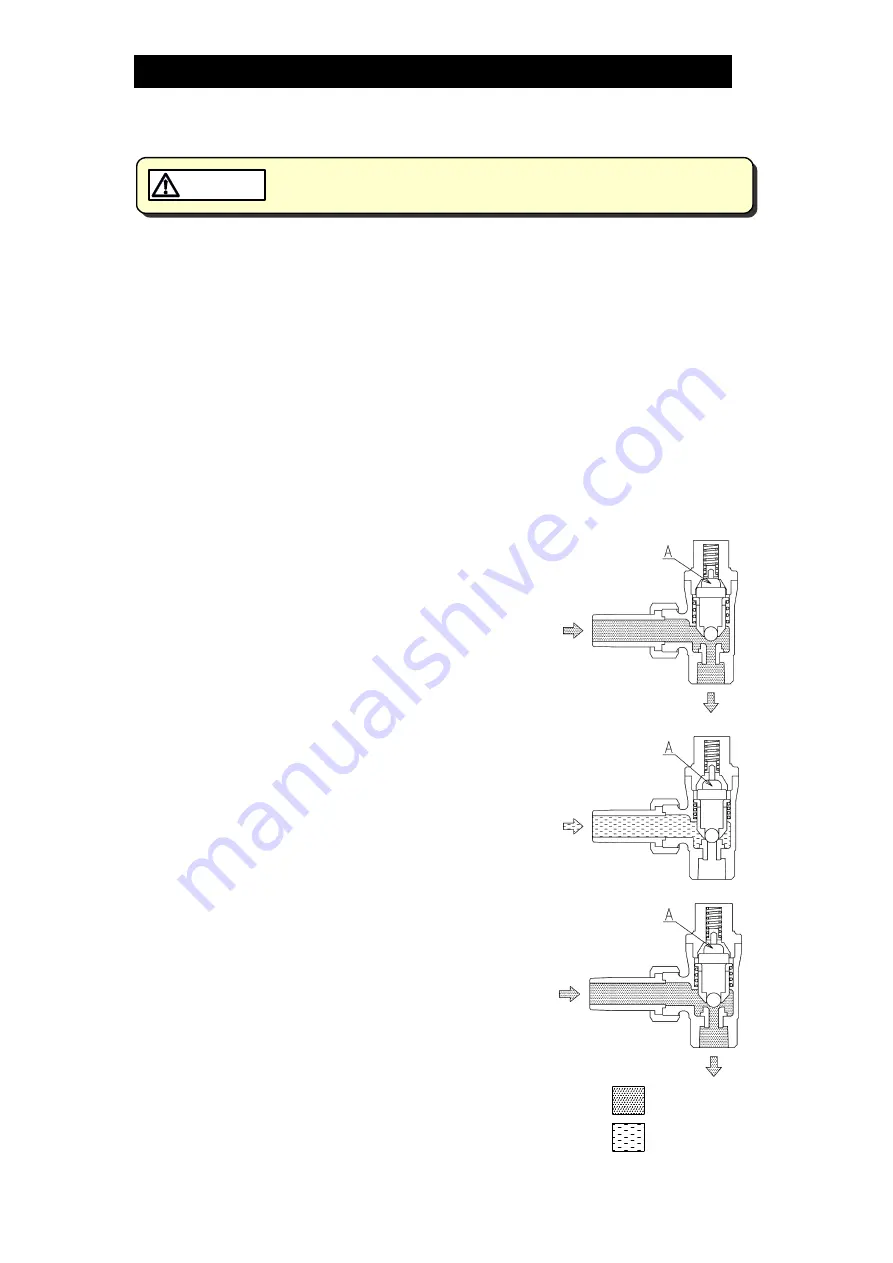

Principles of Steam and Condensate Discharge

1.

At

start-up, temperatures are low so the thermo-

element (A) is contracted, holding the valve open

and allowing the rapid discharge of initial

air and

condensate.

2.

After the discharge of initial condensate, the

temperature of the condensate rises. When it reaches

approximately 100 °C (212 °F), the thermo-element

(A) expands, causing the valve to close.

3. After the valve closes, condensate at approximately

95 °C (203 °F)and below accumulates, causing the

thermo-element (A) to contract again, opening the

valve and discharging the accumulated condensate.

4. When the condensate temperature rises to over

approximately 100 °C (212 °F) again, the valve closes

as in step 2 above.

Condensate

Steam