5

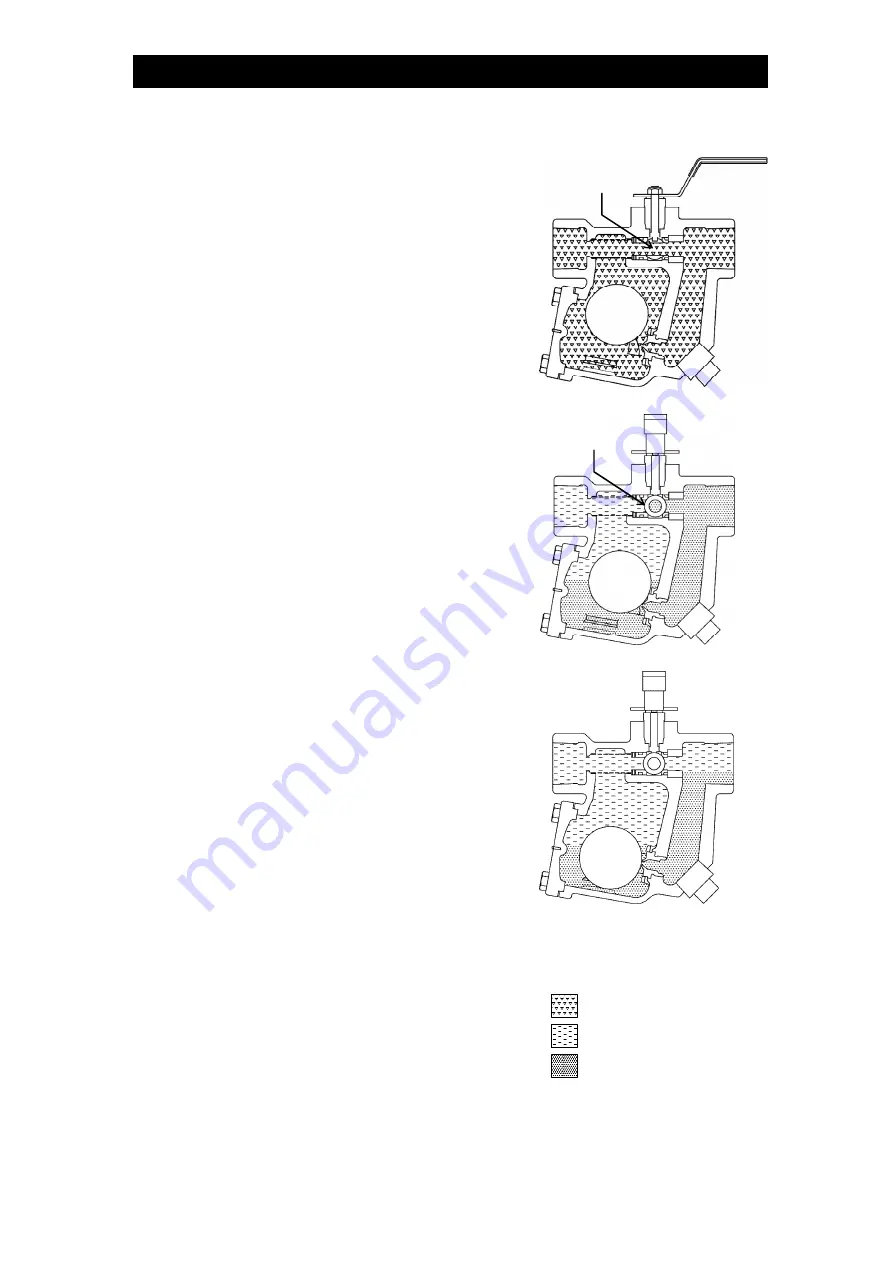

Operation

1. At start-up, the bypass blowdown valve can be

opened to allow a large quantity of condensate

to be rapidly discharged, minimizing the time

required for the unit to warm up. The bimetal

holds the float away from the orifice so that

initial air in the trap chamber is also

discharged.

Bypass Valve:

Opened

2. After the blowdown operation ends, the

bimetal strip retracts and the valve closes, the

float automatically adjusts the valve opening in

response to the fluctuation in load, and the

condensate is continuously discharged

–

no

condensate will accumulate ahead of the

steam trap.

Bypass Valve:

Closed

3. When the amount of condensate flowing into

the chamber decreases, the float gradually

closes the orifice. Steam leakage is prevented

through the use of a 3-point seating design

and the water sealing of the valve. Normally

the bimetal remains retracted and has no

effect on the operation of the float, but if air

should accumulate in the trap and the

temperature drops, it extends, forcing the float

up and the air is automatically vented.

Air, Condensate

Steam

Condensate

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013