172-65694MA-01 (BD800) 25 Jul 2018

13

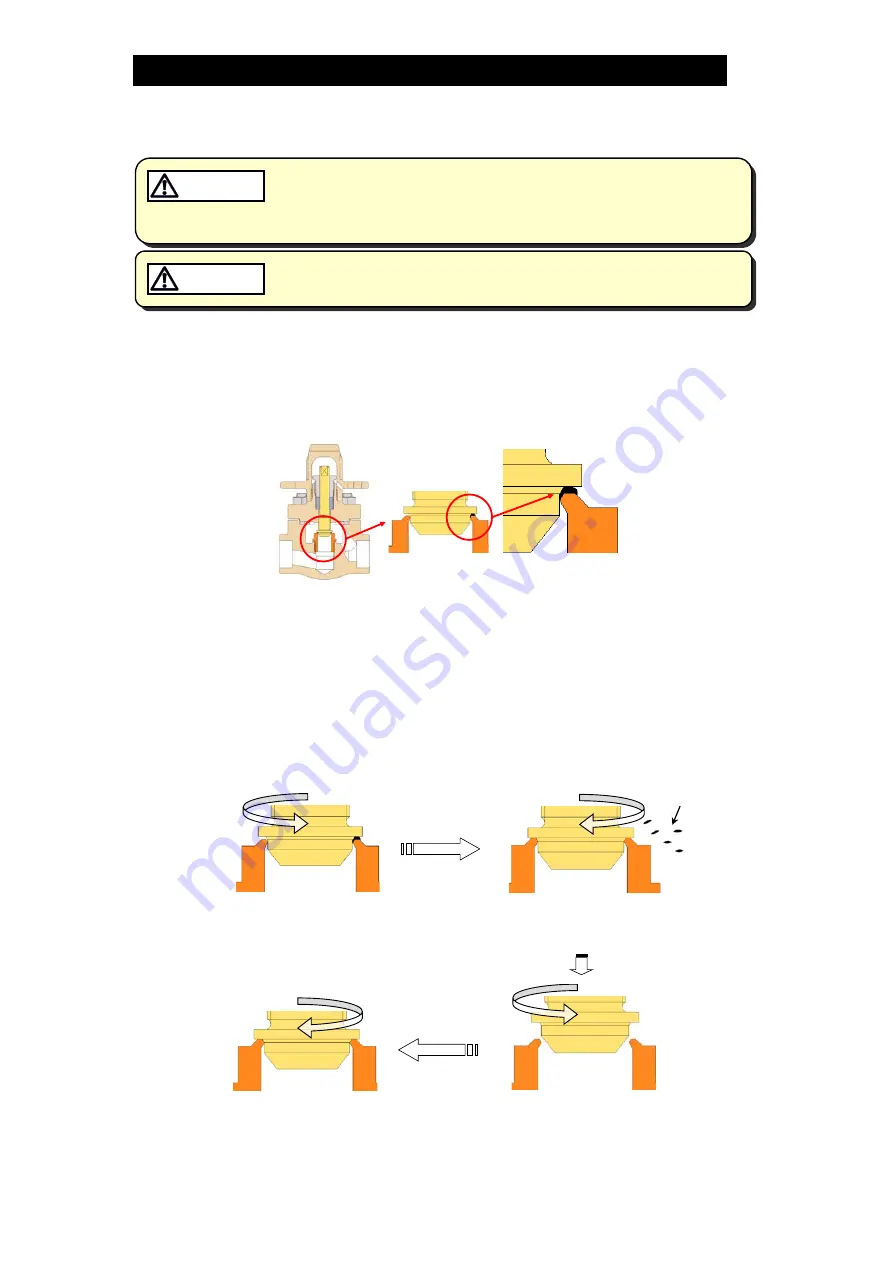

Cleaning the Valve Seat Section

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

When scale adheres to the valve seat section, sealing is inhibited, causing fluid

leakage that affects the work environment.

Restore sealing performance and eliminate fluid leakage by following the steps

described below.

The figure below illustrates scale accumulation between the valve seat and valve

stem resulting in the valve not being able to fully close.

1. Remove the spanner cap.

2. Turn the valve stem counter-clockwise one to two times.

3. Turn the valve stem clockwise (right rotation) until it cannot be turned any further.

4. Repeat steps 2 and 3 two to three times. When the secondary side of the product

is open to the atmosphere, visually check whether fluid is leaking on the

secondary side after performing step 3.

5. When no fluid is leaking and the valve closes fully, cleaning is complete.

If leakage still occurs, repeat steps 2 and 3 another two to three times.

Turn the valve stem

counter- clockwise

Scale is scraped off the valve seat

when turning the valve stem back

clockwise

Cleaning is complete if no

leakage occurs after closing the

valve again

Turn the valve stem counter-

clockwise again

Scale