© Titan Tool Inc. All rights reserved.

21

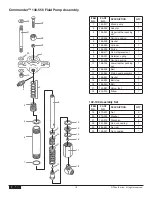

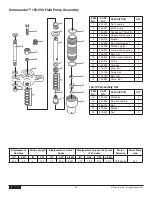

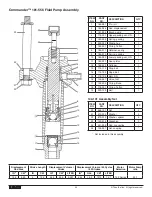

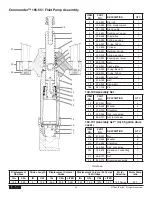

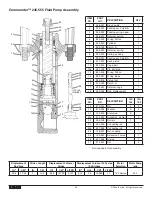

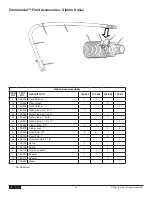

155-559 Fluid Pump Service Information

IMPORTaNT: use of non-Titan manufactured service parts

may void warranty.

The 155 Series Pump should receive a routine servicing after

approximately 1000 hours of use or earlier if there is excessive

leakage from the top packing, or if pump strokes become faster

on one stroke or another. The use of Titan

Lubrisolv Part #

310-200

is recommended as an upper packing lubricant.

DO

NOT SUBSTITUTE oil, water or solvent for an upper packing

lubricant.

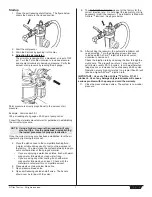

Disassembly Procedure

1. Remove siphon hose assembly.

2. If the pump is connected to an air motor, hold motor piston

rod at wrench flats and unthread coupling nut (1a) to

separate pump from motor.

If the pump is connected to a hydraulic motor, hold motor

piston rod at wrench flats (after removing locking pin with

an allen key) and unthread coupling nut (1) to separate

pump from hydraulic motor.

3. Unthread and remove foot valve (16) and pump cylinder

(12) to separate from pump block (2) and remove ball stop

(13), ball cage (14), ball (15) and O-ring (11).

4. Secure piston seat assembly (10) in a vise and unthread

displacement rod (6) to remove packing set (3), spring (8)

and washer (7).

5. Inspect and clean all parts. Reject cylinder (12) and/or

displacement rod (6) if hard chrome is grooved or worn

through to gray metal.

Reassembly Procedure

NOTE: If cylinder (12) and displacement rod (6) are

reusable then only a minor kit # 155-051 or 155-

055 may be required for reassembly.

1. Place new packing set (3) over piston seat (10) with “V”

packings pointing downward and reassemble with new ball

(9), spring (8), washer (7) and displacement rod (6) in that

order. Tighten and use Loctite on clean threads.

2. Insert new upper packing set (3) into pump block (2).

IMPORTaNT: Peak of “v” packings must point upwards on

reassembly.

Install upper packing spring (4) and spring retainer (5).

3. Insert displacement rod assembly (6) through pump block

(2) holding upper packing set (3) in place with fingers.

4. Lubricate the threaded ends of cylinder (12) including the

new O-rings (11) to protect them on reassembly.

5. Thread cylinder (12) into pump block (2). Do not

overtighten.

6. Place new ball (15), ball cage (14), and ball stop (13) into

foot valve (16) and thread onto cylinder (12). The O-ring

(11) should be lubricated to protect it on replacement of

foot valve. It is not necessary to overtighten as seal is

obtained when parts are fully threaded together.

NOTE: It is not necessary to overtighten foot valve and

cylinder into pump block. O-ring seals perform

sealing function without excessive tightening.

Full thread engagement is sufficient. The foot

valve (16) may be rotated back up to 1/2 turn from

full engagement for convenient hose position.

For siphon hose attachment, it is critically important that

the thread of the siphon hose fit snugly into the foot valve

with the hose assembly couplings Teflon-taped and sealed

to prevent air inlet leakage.

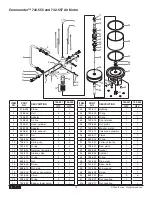

Service Kits

Pump Service Kits, minor

ITEM

NO.

PaRT

NO.

DEScRIPTION

155-

051

155-

055

3

155-052

Packing set, leather

2

3a

155-053 Packing set, leather/poly.

2

9

155-225

Ball, S.S.

1

1

11

891-373 O-ring

2

2

15

178-700

Ball, S.S.

1

1

426-051 Loctite sealant

1

1

Pump Service Kits, major

ITEM

NO.

PaRT

NO.

DEScRIPTION

155-

500

155-

505

155-051 Minor service kit

1

155-505 Minor service kit

1

6

155-981

Rod, displacement

1

1

12

155-932 Cylinder

1

1

Содержание SPEEFLO Admiral 830-331

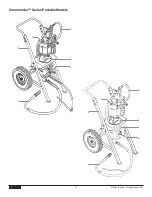

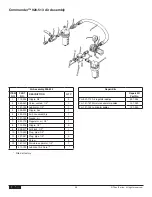

Страница 12: ...12 Titan Tool Inc All rights reserved Commander Series Portable Models 1 3 3 7 7 2 5 6 4 2 8 8 1 ...

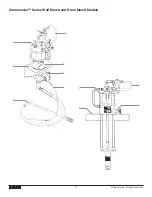

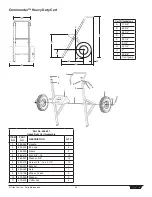

Страница 14: ...14 Titan Tool Inc All rights reserved Commander Series Wall Mount and Drum Mount Models 1 4 9 3 1 2 2 6 6 8 5 ...

Страница 39: ... Titan Tool Inc All rights reserved 39 Notes ...