15

8.1.3 MONTHLY

8.1.4 BIMONTHLY

8.1.5 YEARLY

8.1.6 EVERY OTHER YEAR

1. Check safety mechanism operation.

2.

Check condition of shafts, shaft locks and bushings.

3. Check overall cleanliness.

1. Check condition of extensions and lubricate.

2. Check oil leaks from cylinders.

3. Check oil leaks at pipe joints.

Service and safety inspection on the lift must be performed by a competent person. This

inspection must be recorded. If the 12 month service and safety inspection is not performed,

the warranty is null and void.

1. Lubricate chain

2.

Grease rub blocks and column surface contacting rub blocks.

3.

Change the hydraulic fluid. A good maintenance program makes it mandatory to keep

hydraulic fluid clean. Operating temperature, type of service, contamination levels,

filtration, and chemical composition of fluid should be considered. If operating in harsh or

dusty conditions, a shorter interval may be required.

THE FOLLOWING ITEMS SHOULD ONLY BE PERFORMED BY A TRAINED

MAINTENANCE EXPERT.

• Replace hydraulic hoses.

• Replace chains and rollers.

• Replace cables and sheaves.

•

Replace or rebuild air and hydraulic cylinders as required.

•

Replace or rebuild pumps / motors as required.

•

Check hydraulic and air cylinder rod and rod end (threads) for deformation or damage.

•

Check cylinder mount for looseness and damage.

Relocating or changing components may cause problems. Each component in the system

must be compatible; an undersized or restricted line will cause a drop in pressure. All valve,

pump, and hose connections should be sealed and/or capped until just prior to use. Air

hoses can be used to clean fittings and other components. However, the air supply must be

filtered and dry to prevent contamination. Most important -

CLEANLINESS

- contamination is

the most frequent cause of malfunction or failure of hydraulic equipment.

Hydraulic oil should be replaced.

Содержание HD2P-15000C

Страница 24: ...20 FIG 1 DIMENSIONS 148 3 8 179 3 8 120 3 4 172 3 8 Min 5 Max 76 1 2 4 3 4 3 R37 1 8 52 1 8 11 DIAGRAMS FIG 1 9...

Страница 25: ...21 FIG 2 ARM SWING 148 3 8 Min 5 Max 7 4 3 4 3 34 1 2 R37 1 8 52 1 8 R37 1 8 52 1 8...

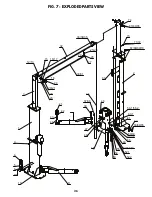

Страница 26: ...22 FIG 3 COLUMN OVERVIEW...

Страница 27: ...23 FIG 4 CABLES Locking Nuts 4 Bottom Cable Sheave Equalizing Cable 2 Top Cable Sheave...

Страница 29: ...25 FIG 6 ANCHORING Column Anchor Bolts 3 4 x61 2 Column Concrete 3000PSI min 148 34 1 2 107 6 201 2 3 4 H...

Страница 36: ......

Страница 37: ...NOTES...

Страница 38: ...NOTES...

Страница 39: ...NOTES...