11

6. OPERATION INSTRUCTIONS

WARNING: LIFT OPERATION BY TRAINED AUTHORIZED PERSONNEL

OVER 18 YEARS ONLY. APPLY THE PARKING BRAKE AFTER POSITIONING THE

VEHICLE ON THE LIFT. DO NOT ALLOW ANYONE TO STAY IN LIFT AREA DURING

RAISING AND LOWERING CYCLES. CLOSELY WATCH THE VEHICLE AND THE

LIFT DURING RAISING AND LOWERING CYCLES. OBSERVE THE RATED LOAD

CAPACITY AND LOAD DISTRIBUTION. DO NOT ALLOW ANYONE TO CLIMB ON

LIFT OR STAY INSIDE VEHICLE. AFTER RAISING THE VEHICLE FRAME 6”, STOP

AND CHECK ADAPTERS FOR SECURE CONTACT. PERFORM BUMPER TEST(PG.2).

MAKE SURE THE VEHICLE DOORS ARE CLOSED DURING RAISING AND

LOWERING CYCLES.

WARNING: IN CASE OF DEFECTS OR MALFUNCTIONS SUCH AS JERKY

LIFT MOVEMENT OR DEFORMATION OF THE SUPERSTRUCTURE, SUPPORT OR

LOWER THE LIFT IMMEDIATELY. CONTACT QUALIFIED SERVICE PERSONNEL.

WARNING: PAY CLOSE ATTENTION WHEN SETTING THE LOCKS. THE

LOCKS MUST BE A LEVEL MATCH SET IN ORDER TO AVOID A VEHICLE TILT.

WARNING: ALWAYS LOCK THE LIFT BEFORE GOING UNDER THE

VEHICLE. NEVER ALLOW ANYONE TO GO UNDER THE LIFT WHEN RAISING OR

LOWERING.

6.1 DEFECTS / MALFUNCTIONS

6.2 CONTROLS

Once the up button is actuated, the lift moves up until the button is released or the limit stop

is reached.

6.2.1 UP CONTROL

6.2.2 SAFETY LOCK CONTROL

The safety latch mechanism will “Trip Over” as the lift raises and drop into each safety latch

stop. To lock the lift you must press the lowering handle on the power unit (Fig. 1) to relieve

the hydraulic pressure and let the safety locks engage into a level locked position.

Содержание HD2P-11000ACX

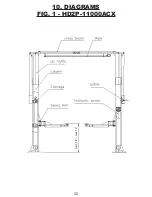

Страница 23: ...20 10 DIAGRAMS FIG 1 HD2P 11000ACX min 5 3 8 max 72...

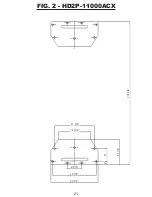

Страница 24: ...21 FIG 2 HD2P 11000ACX 17 3 8 14 3 16 6 3 8 18 7 8 20 1 2 2 9 17 1 4 137 3 8...

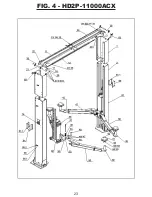

Страница 26: ...23 FIG 4 HD2P 11000ACX...

Страница 27: ...24 FIG 5 HD2P 11000ACX...

Страница 28: ...25 FIG 6 HD2P 11000ACX...