10.1 Rules of operations

To ensure the Boom Barrier continuous and reliable operation it is necessary:

џ

to use the product according to its intended purpose;

џ

all rules specified in this Manual shall be strictly observed during operation;

џ

to provide maintenance and repair of equipment in due time;

џ

to prevent the Boom Barrier operation and maintenance to be performed by unauthorized

persons;

It is forbidden:

to touch the Boom Barrier arm during its operation;

to prevent Boom Barrier raising/sinking;

to initiate movement of vehicles prior to complete Boom Barrier sinking

10.2 Equipment maintenance:

The Boom Barrier maintenance includes preventive measures to be taken according to the established frequency

to maintain Boom Barrier in operational condition, decrease component wearing and prevent faults and

malfunctions.

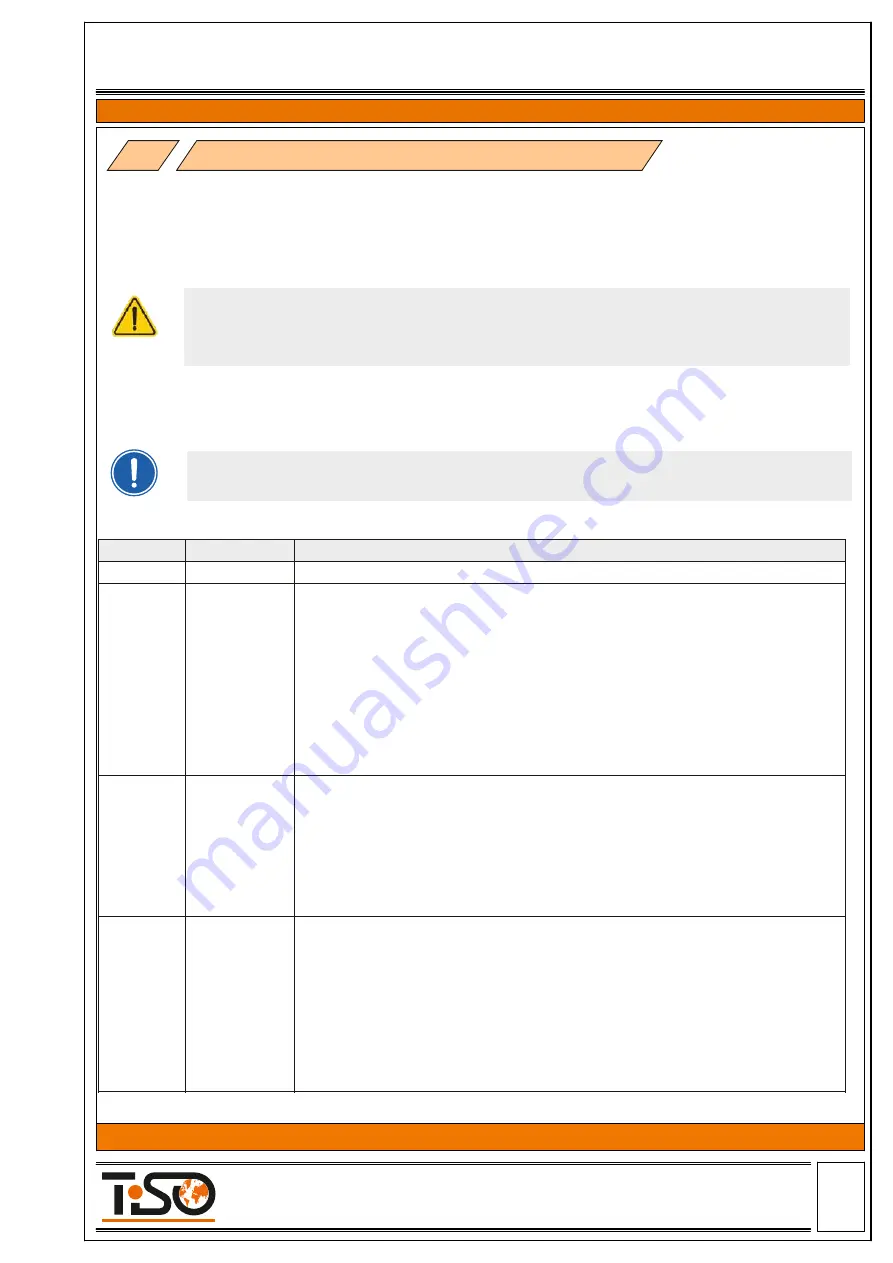

10.

Boom barrier operation regulations

M type

Frequency

Scope of control/work

1

2

3

Daily

inspection

each shift

Daily maintenance is performed before commencement of work and includes:

- visual inspection of Boom Barrier;

- if required, prompt mechanical troubleshooting, elimination of corrosion and

surface pollution;

- availability of all units and sensors in their proper locations and their

fastening are reliable;

- performance of all sensors and cable integrity;

- Boom Barrier normal operation without jerks and abnormal noises, jamming of

movable constructional elements;

- motor heating (over 70°C).

M-1

monthly

M-1 is performed monthly and includes the following measures:

- measures in the scope of daily inspection;

- elimination of dust and dirt from the Boom Barrier housing and components;

- cleaning of actuators, sensors and actuators;

- verification of sensors fixation reliability and their performance;

- verification of good condition and fastening security of cable connections to

actuators, sensors;

- check of availability and integrity of protective fences and devices.

M-2

semiannually M-2 maintenance is performed semiannually including the following types of work:

- measures in the scope of M-1;

- verification of fastening security of units and devices;

- check of lever tightening;

- check of spring, circuit and relative anchors;

- check of barrier arm balance;

- make sure that at the end of stroke the lever is horizontal and / or upright

position;

- check of operation of control unit and safety devices;

The equipment examination and maintenance to be performed according to

the Schedule and only by the properly qualified professionals.

Table 8

- Boom Barrier maintenance schedule

Page

-22-

Size А4

Installation and Operation Manual

Revision 1.0 2021

ROAD BLOCKING SYSTEMS

Office and Production site:

Tel.:

+380 (44) 291-21-11

14 Promyslova str., 02088, Kyiv, Ukraine,

Fax:

+380 (44) 291-21-02

E-mail:

[email protected] www.tiso.global

BOOM BARRIER OPTIMUS