TIMBERWOLF

TW 150DHB

20

NOTE: This should be done regularly. In dirty and dusty conditions or during periods of hard

work it should be weekly. If the bearings and splines are allowed to run dry premature wear will

occur resulting in a breakdown and the need for replacement parts. This failure is not warranty.

Early signs of insufficient grease includes squeaking or knocking rollers.

NOTE: This should be done regularly. In dirty or dusty conditions or during periods of hard

work it should be done weekly. If the slides become dry the top roller will tend to hang up and

the pulling-in power of the rollers will be much reduced. Excessive wear will ensue.

1. Turn the chipper off and remove the ignition keys.

2. Ensure machine has come to a complete stop - remove battery leads.

3. Remove the bolt and washer retaining roller box guard and lift guard.

4. Remove the two springs on the roller box slide.

5.

NOTE: Rollerbox slide weighs in excess of 20kg.

Lift the top

roller and wedge a suitably sized piece of wood to hold in place.

6. Apply thin grease with a brush to each slide on roller box and on

inner cheeks of slider.

DO NOT USE GRAPHITE BASED GREASE.

7.

NOTE: Rollerbox slide weighs in excess of 20kg.

Remove

wedge, lower roller box slide and replace springs.

8. Close roller box guard making sure that it is located over the retaining

bracket, and ensure bolt and washer (as note 3) are tightened.

9. Refit battery leads.

6

3

2

5

4

1. Remove bolt and washer retaining roller box guard and lift guard (see

diagram on page 18).

2. Locate two grease nipples; one in the centre of each roller shaft.

3. Use a pump action grease gun to apply a generous amount of grease

to each roller drive.

DO NOT USE GRAPHITE BASED GREASE.

After applying grease, to penetrate all the bearing surfaces thoroughly,

start the machine and operate the rollers for 20 seconds. Switch off the

machine. Repeat this greasing/running procedure a further 3 times.

4. Close roller box guard making sure that it is located over the retaining

bracket, and ensure bolt and washer are tightened.

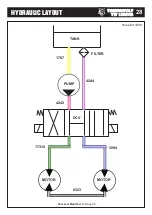

All the hydraulic hoses should be regularly inspected for chafing and leaks. The hydraulic system is

pressurized to 130 Bar and thus the equipment containing it must be kept in good condition.

Identify the hoses that run to the top motor. These have the highest chance of damage as they are

constantly moving. If any hydraulic components are changed new seals should be installed during

reassembly. Fittings should then be retightened.

GREASE THE ROLLER SPLINE AND BEARING

GREASE THE ROLLER BOX SLIDES

GREASING ROTOR BEARINGS

ENGINE SERVICING

CHECK HOSES

Both front and rear bearings are sealed and do not need greasing.

SERVICE INSTRUCTIONS

All engine servicing must be performed in accordance with the Engine Manufacturer’s Handbook

provided with the machine.

FAILURE TO ADHERE TO THIS MAY INVALIDATE WARRANTY AND/OR

SHORTEN ENGINE LIFE.

Содержание TW150DHB

Страница 24: ...TIMBERWOLF TW 150DHB 23 EXAMPLE IDENTIFICATION PLATE ...

Страница 27: ...TIMBERWOLF TW 150DHB 26 ELECTRICAL PARTS LOCATOR Date Last Modified 16th May 06 ...

Страница 30: ... blank page ...

Страница 37: ...TIMBERWOLF TW 150DHB 36 DISCHARGE ...

Страница 43: ...TIMBERWOLF TW 150DHB 42 FUEL TANK ...