Installation, use and maintenance guide

COMPACT S22

–S26–S32 EVO5

Page

8

ENG

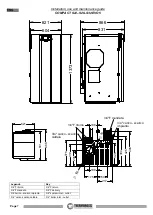

3 – GENERAL DESCRIPTION

3.1 OPERATING TECHNOLOGY

Your appliance has been built to fully satisfy all your heating and practical requirements. Top-grade components and functions

managed with microprocessor technology guarantee high reliability and optimal performance.

3.2 THE PELLET

The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; it his allows you to fully enjoy the heat of the flame

without having to manually stoke the combustion.

The pellets have a 6 mm diameter and a length between 10 e 20 mm. They have a max moisture content of 8%; a thermal value of

4000/4500 Kcal/kg and density of 630-640 kg/m³. It must be approved according to UNI EN 14961-2 A1 A2.

It is strictly forbidden to use any pellet type other than that specified above. The use of fuel that does not comply with the

above specifications not only immediately invalidates the warranty for the appliance but can also create dangerous

situations. Do not use the appliance as an incinerator, at the risk of voiding the warranty.

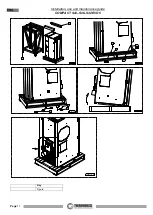

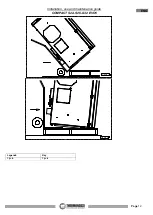

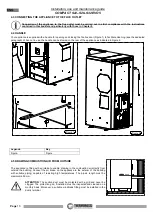

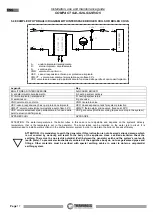

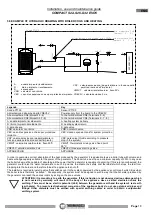

3.3 PELLET REFUELLING

The feedbox is situated in the top part of the appliance. The

load capacity specified in the technical data can vary

according to the specific weight of the pellets.

Take special care when loading the tank as the screw feeder

at its base is in motion. Take care when topping up with fuel

as the loading area can get very hot.

ATTENTION: It is normal to find some pellets remaining in the tank

even if the appliance shuts off because the pellets have run out.

Attention: when filling up the tank, take care not to drop any pellets into the internal parts of the appliance, as, in

extreme cases, this could generate live flames.

The manufacturer recommends emptying the tank and vacuuming the screw feeder zone once a month and during the

summer period.

Only pellets complying with the above specifications are to be loaded into the tank; in no case whatsoever must foreign

substances or objects be introduced into the tank, the brazier or any part of the generator.

Revisione

Autore

Data

Descrizione

LAMIERA

Il fornitore è responsabile della corretta realizzazione del

particolare come indicano le viste di progetto; lo sviluppo

piano deve essere verificato ed eventualmente modificato dal

fornitore in funzione delle macchine di piegatura che

andranno a realizzare il particolare.

STAMPI E FUSIONI

É obbligo da parte del fornitore, prima di

realizzare qualsiasi attrezzatura, fornire a

THERMOROSSI S.p.A. i file

tridimensionali dei particolari definitivi

Il presente disegno è di proprietà esclusiva di THERMOROSSI S.p.A.. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguito secondo i termini di legge in vigore.

09/09/2015

Scala

Locazione file

Data

F

irm

a

Foglio

Note

Materiale

Prodotto

Sviluppo

1/1

TEL. 0445-741310 - FAX 0445-741657

Via Grumolo, 4 - 36011 ARSIERO (Vicenza) - ITALY

S.p.A.

Spessore

x

Approv

.

D

at

a

appro

v

.

Formato

Paragrafo 3 _3_32

Cod.

Disegnatore

Volume

Peso

Colore

Revisione

66576193.340 kg

69979207.36 mm^3

R:\Tecnico\DWG\Solid_edge\COMPACT RESTYLE\COMPACT 32 RAL 9006__LIBRETTO USO E MANUTENZIONE\Paragrafo 3 _3_32.dft

Descrizione

#