Installation, use and maintenance guide

ARDHEA EVO5

– ARDHEA-F EVO5

Page

15

ENG

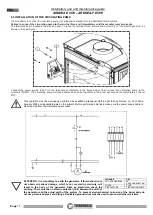

5.5 SCHEMATIC DIAGRAM OF TYPICAL CLOSED EXPANSION TANK HYDRAULIC SYSTEM WITH PUFFER

TANK

ATTENTION: it is mandatory to earth the generator. If this instruction is not observed serious damage, which

is not covered by warranty, will result to the body of the appliance. Have a skilled electrician check the

earthing. There must be no electric pote

ntial (Volt) between the generator earth and the system’s real earth

(earth plate). To prevent electrochemical corrosion of the appliance body do not use galvanised pipes and

fittings. Other materials must be earthed with special earthing cables in order to obtain a unipotential

earthing system.

ATTENTION:

Anti-condensation mixing valve should be set at approx. 65°C. So when the temperature of the boiler

drops below this value, the “cold” inlet closes and prevents circulation towards the puffer tank but only between the

boiler supply and return. In this way, the heat stored in the puffer tank is not dispersed to the boiler.

A

Supply to the puffer tank

SCA

Discharge

ACQ

Water main inlet

SCS

Safety heat exchanger

PC

System circulating pump

VEC

Additional closed expansion tank, sized to at least 10% of

the volume of water contained in the system

R

System return if integrated with a solar system

VM3VT

Anti-condensation mixing valve

R1

Return from the puffer tank

VNR

Nonreturn valve

S

On-off valve

VS

Safety valve 3 bar

SC

Gate valve

(throttle according to pressure drop in the system)

VST

Thermal relief valve

VASO CHIUSO -+ PUFFER

VNR

VEC

ACQ

VM3VT

SC

VNR

S

SCA

VS

A

R

S

S

S

COLD

MIX

H

O

T

R1

VST

SCS

PC