6

the system. This prevents the formation of toxic

gases, corrosive acids, and scale.

CAUTION: Do not use soft solders. For copper-to-

copper joints use a copper-phosphorus braze alloy

(BCuP per the American Welding Society) with 5%

(BCuP-3) to 15% (BCuP-5) silver content. Only use a

high silver content brazing alloy (BAg per AWS) for

copper-to-brass or copper-to-steel joints such as a

45% (BAg-5) silver content. Only use oxy-acetylene

brazing.

Refrigeration Piping Design

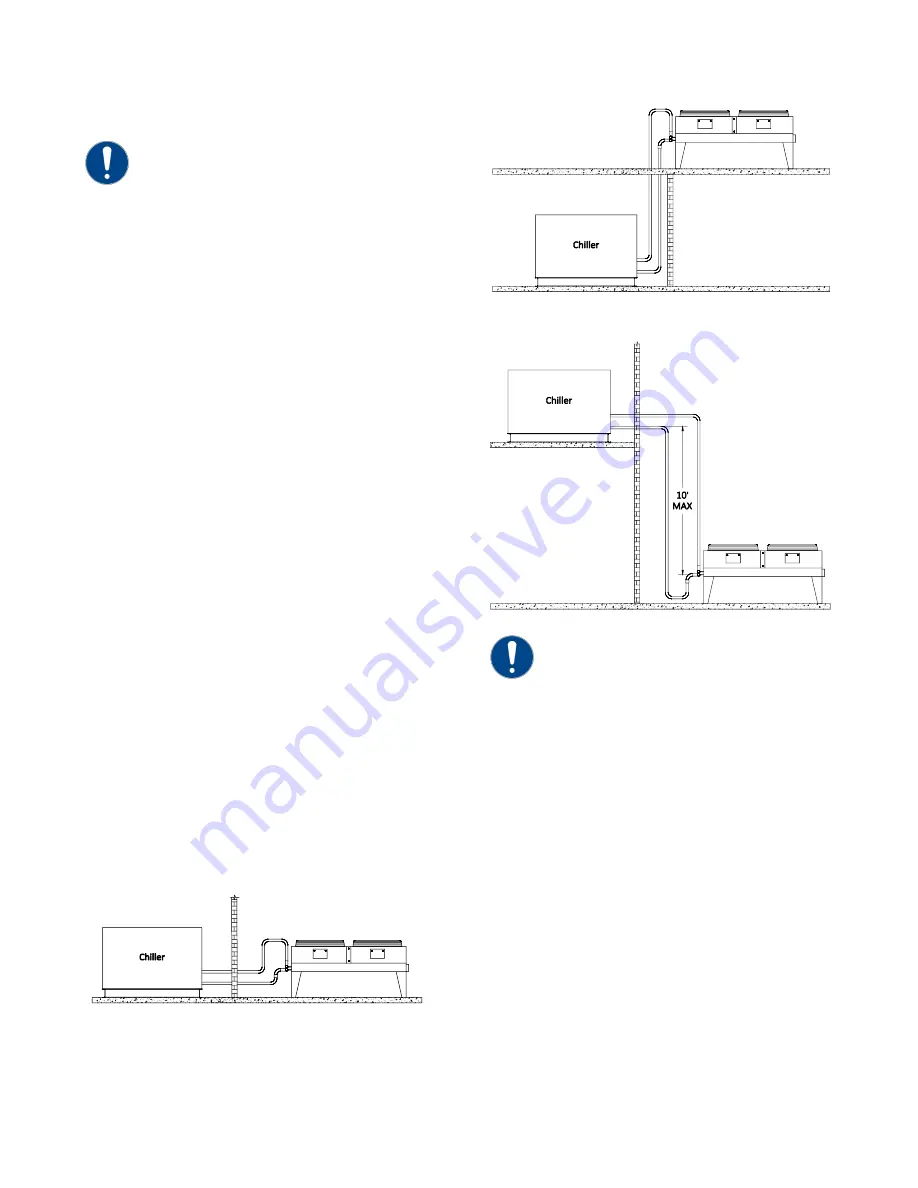

The system is configurable as shown in Figure 1,

Figure 2, and Figure 3. The configuration and its

associated elevation, along with the total distance

between the chiller and the air-cooled condenser,

are important factors in determining the liquid line

and discharge line sizes. This will also affect the field

refrigerant charges. Consequently, it is important to

adhere to certain physical limitations to ensure the

system operates as designed.

General Design Considerations

1.

The total distance between the chiller and the

remote air-cooled condenser must not exceed

200 actual feet or 300 equivalent feet. Keep the

distance as short as possible.

2.

Liquid line risers must not exceed 15 feet in

height from the condenser liquid line

connection.

3.

Discharge line risers cannot exceed an elevation

difference greater than 100 actual feet without a

minimum of 2% efficiency decrease.

4.

To form a proper liquid seal at the condenser,

immediately drop at least 15 inches down from

the liquid outlet before routing the piping to the

chiller. Make the drop leg before any bends or

angles connecting to the remainder of the liquid

connection piping.

Figure 1 – Condenser at Chiller Level

Figure 2 – Condenser Located Above Chiller Unit

Figure 3 - Condenser Located Below Chiller Unit

Note: Liquid line sizing for each chiller capacity is in

Table 10. These line sizes are listed per circuit and

apply where leaving water temperature (LWT) is 40°F

or higher. For applications where the LWT is below

40°F, size lines using the ASHRAE Refrigeration

Handbook or other suitable design guide.

Determining Equivalent Line Length

To determine the appropriate size for field installed

liquid and discharge lines, it is first necessary to

establish the equivalent length of pipe for each line.

The equivalent length is the approximate friction loss

from the combined linear run of pipe and the

equivalent feet of elbows, valves, and other

components in the refrigeration piping. The sum

total is the equivalent length of pipe that would have

the same pressure loss. See the ASHRAE

Refrigeration Handbook for more information.

Follow these steps when calculating line size

1.

Start with an initial approximation of equivalent

length by assuming that the equivalent length of

pipe is 1.5 times the actual pipe length.