# First time flyer should never fly by himself / herself. Assistance from experienced flyer is absolutely necessary.

# Pre-flight adjustment must be done before flying, it is very dangerous to fly a badly pre-adjusted aircraft.

# is specially designed to be powered by

2C 0.40 engine

or

450W motor system.

# Make sure the air field is spacious, never fly the plane too close to people and never get too close to a running

propeller. Extreme caution should be exercised when working with electric powered models. Make sure the

propeller is cleared of all objects, especially your hands before connecting the battery to the model. Make sure

you understand the operation of the ESC (Electronic Speed Control) by studying the ESC manual. Once you

plug in the battery for electric powered model, always treat the propeller as a rotating one, as accidental

movement of the throttle stick will spin the propeller and could cause injuries.

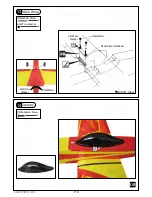

# If you find wrinkles on the covering as a result of weather changes, you can use hot iron to remove the wrinkles.

Please begin with lower temperature setting and gradually raise the temperature until the wrinkles are gone.

Too hot an iron may damage the covering.

Don't use hot iron near the seams or edges, hot iron will melt the glue

and shrink the covering at the same time, causing the seams to pull away.

# Check and re-tighten up all factory assembled screws, use thread locker if necessary.

Wingman ll

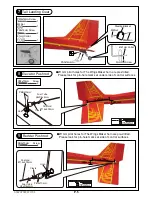

C.G.

The ideal C.G. position is 76mm (3 in.) behind the leading edge

measured at where the wing meets the fuselage. In order to obtain

the C.G. specified, add weight to the fuselage or move the battery

position. Check the C.G. before flying.

76 mm

76 mm

C.G.

3 in

3 in

P.11

17

Warning!

Important Safety Precautions

GA029PO22471104

Содержание Wingman II

Страница 15: ...GA029PO22471104 ...

Страница 16: ...GA029PO22471104 THE WINGS MAKER www thewingsmaker com ...