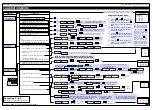

Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

5

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

0 Functions Activated

by Pressing the

PROGRAM Button

1 Calibration

Procedures

2 Related Calibration

Functions

3 -

CALIBRATION MODES FOR INPUT AND OUTPUT

0 No function

1 On Demand TARE from the PROGRAM button

2 On Demand Single-point Calibration from the PRO-

GRAM button (requires single input source)

3 On Demand Two-point Calibration from the PROGRAM

button (requires dual input source)

4 On Demand Primary Input Compensation Mode from

the PROGRAM button

5 On Demand Manual Loader Mode (no increase /

decrease with HOLD active)

6 -

7 -

Note:

When in the TARE mode, a decimal point appears at the right

of the display indicating that the tare value is NOT zero.

OBJECT FOR 2nd DIGIT

0

Result

1

Channel 1

2

Channel 2

3

Channel 3

4

Channel 4

CALIBRATION MODE

FIRST DIGIT

SECOND DIGIT

THIRD DIGIT

0 Serial Communications Properties

1 Set Auto Zero Maintenance for 3rd digit

2 Set Averaging Samples & Averaging Window for 3rd digit

3 Totalizer Settings Mode

4 Setup 32-point Linearization Tables

5 Scale Analog Output LOW/HIGH Display Readings

6 -

7 -

Use but-

tons to set SPAN

Use

buttons to set

OFFSET

Use but-

tons to set ZERO

Use buttons

to set SCALE

Use buttons

to set SPAN

P

P

For detailed calibration procedures, see

Calibration Procedures Supplement (NZ203)

Press the PROGRAM button for 4 seconds to tare the selected channel

P

P

4 secs

P

4 secs

Use

buttons to set

ZERO

Use buttons

to set SPAN

P

4 secs

P

4 secs

P

P

Use buttons

to set baud rate

Use but-

tons to set parity

Use

buttons to set

address from 1 to 255

Use

buttons to set LOW

display reading [CAL_L]

Use

buttons to set

HIGH display reading [CAL_h]

Use buttons

to set CAL_h

Use buttons

to set time period

Use buttons

to

set total from 1-65535

Select the method of configuring the user defined linearization

table:

manual

or

auto

setup mode. Then set the table number,

date, and serial number before setting the linearization points.

Or select [init] to re-initialize the default table settings.

P

P

P

P

P

P

Use buttons

to

set averag-

ing samples from 0 to 255 counts

Use

buttons to set averaging

window from 0 to 65535 counts

P

Use buttons

to set AZ_M from 0

to 255 counts

P

Auto zero capture band

For detailed calibration procedures, see

Calibration Procedures Supplement

Use

buttons to ADJUST primary input compensa-

tion value from –19999 to 99999 on CH2 ONLY

Use

buttons to set

time delay in milliseconds

Except ASCII Mode which uses message terminators:

Use buttons

to set AZ_A from 0 to

65535 counts

P

Auto zero motion

Auto zero aperture window

0

-

1

Analog Output 1

2

Analog Output 2

THIRD DIGIT

0

-

1

Analog Output 1

2

Analog Output 2

THIRD DIGIT

Note:

The input channel setting in

the 3rd digit is

not

relevant to

the

manual setup mode

.

0

-

1

Total 1

2

Total 2

THIRD DIGIT

Use

buttons to ADJUST analog output 1 or 2 value

from –19999 to 99999 via the manual loader output

Default setting 10,000 counts

0

-

1

CH1

2

CH2

3

CH3

4

CH4

THIRD DIGIT

P

P

Use buttons

to set Cutoff from

–19999 to 32767

P

Use buttons

to

set rollover to ON or OFF

P

Use buttons

to set to 7 or 8 bits

If Code 3 set to Master

Mode [XX2] ONLY

$

= minimum 50 ms delay

*

= minimum 2 ms delay

Use buttons

to set input rate

Note:

The correct input signal channel must be

selected in the 3rd digit when configuring a lin-

earization table using the

auto setup mode

.

Use

buttons to set

AZ_C from 1 to 254 counts

Rate-of-change in counts/second

This is the default 3rd digit box. If not pointing to another 3rd digit

box, all 2nd digit settings should be regarded as pointing to here.

0 Manual Calibration

(requires NO input source)

1 2-point Calibration (requires dual input source)

2 Calibrate Thermocouple (requires K type thermocouple

input source)

3 Calibrate RTD (requires RTD 385 input source)

4 Calibrate Smart Input Module.

Note: This function is not available on all input modules

5 Calibrate Analog Output mA/V (Single analog out requires

multimeter connected to pins 2 and 3 on Terminal 4)

6 -

7 -

Converting °F to °C

See User Notes on Page 20 for a procedure.

2

1

3

+

+

Dual

Analog

Output

(ADV)

Analog Output

TERMINAL 4

All smart input modules have individual calibration procedures.

See the specific smart input module data sheet for setup procedures

Use buttons

to set CAL_L

Using the Calibration Mode

1)

Press the

and

buttons at the

same time. The controller enters the

brightness menu [BRI]. Press the

button again to enter the Calibration

Mode.

2)

With [CAL] [XXX] toggling on the dis-

play, set the 1st, 2nd, and 3rd digits to

their required settings.

3)

Press the

button to enter the select-

ed sub-menu and select the required

calibration settings from the sub-menus

displayed.

4)

Press the

button repeatedly to

return to the operational display

(bypassing Codes 1 to 9).

P

P

P

P

Note:

Once the 3-digit settings

have been entered for an

on-demand function [CAL]

[0XX], pressing the

button saves the selected

on-demand setting and

moves to Code 1.

When in the operational

display, press the

but-

ton for 4 seconds to acti-

vate the selected on-

demand function and dis-

play the relevant sub-menu

settings (except [01X]

which has no sub-menu).

P

P