Operation Manual – TEXI 781 SERVO

Adjustment method:

(1) Insert the positioning ruler between the needle bar and the needle plate, loosen the needle bar,

and tighten the screws to adjust.

Note: the needle should fall in the center of the needle plate.

The phenomenon when the adjustment value changes:

When sewing elastic fabric, the needle bar is lowered a little more than the standard value, and

the effect is better.

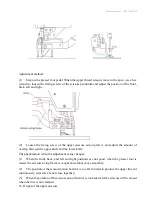

2. The cooperation of the needle and the hook:

Adjustment requirements:

When the needle bar is lifted by 2.3mm from the lowest point, the center of the hook tip and the

needle should be the same, and the upper end of the needle eye is 1.6~1.8mm; the lateral gap

between the needle and the hook tip is about 0.05mm.

Adjustment method:

(1)

With the needle bar rising from the lowest point, place the positioning scale 2 between the

needle bar and the needle plate, and then loosen the set screw of the hook sleeve to adjust.

(2)

At this time, adjust the lateral clearance of the needle and the hook tip to about 0.05 mm,

and swing it to the left and right to check and not touch.