08354B DCN7877

Teledyne API T640 PM Mass Monitor

78

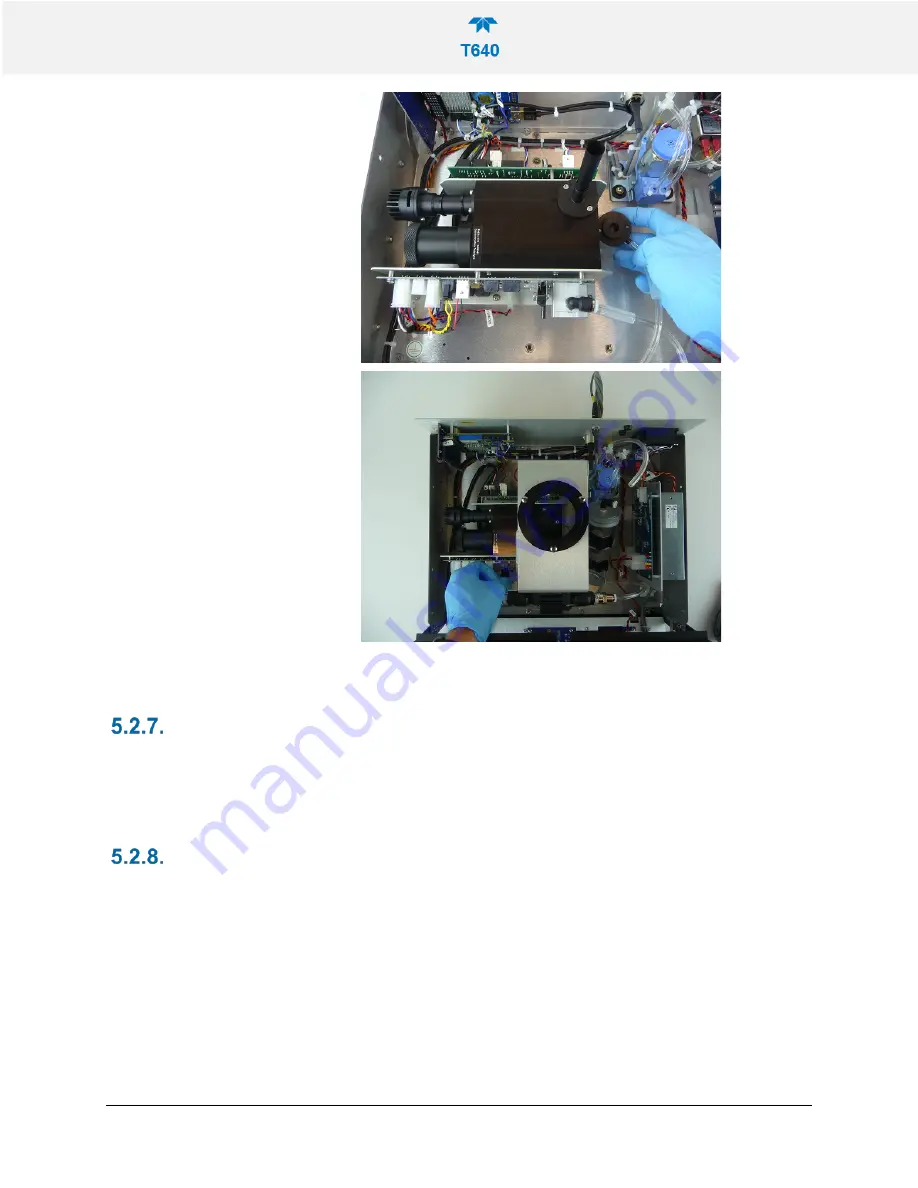

9. Close instrument and turn power on. Wait until the LED temperature stabilizes,

and then perform a PMT sensor check with the SpanDust™ (Section 4.5).

INSPECTING THE SAMPLING LINE

Look inside the sampling line for debris or dust on the walls. If needed, push a rag

or a paper towel through the line; then use a can of compressed gas made

specifically for electronics to blow through the line for final cleaning.

CHECKING FOR LEAKS

The internal components of the T640 are not meant to be under strict vacuum as

what would normally be done in a leak test. So, to avoid damage to internal

components, it is recommended that the inlet never be capped (air tight) while the

instrument pump is running.

The Leak Check (

Zero Test)

is a way to check for leaks that do not involve pulling

a vacuum on the system.

1. Navigate to the Calibration>Leak Check menu (Figure 4-6).

2. Press Start.