4

©2019 Tecumseh Compressor Company LLC. All rights reserved.

TPC Part #71511 | Rev A 05/13/2019

www.tecumseh.com

ELECTRICAL CONNECTIONS

(Continued)

Refer to “Minimum Circuit Ampacity” and “Maximum Fuse Size” data on the unit nameplate and applicable

electrical codes to size the electrical wires, fuses and over current protection devices.

Refer to wiring diagram (attached inside of the electrical cabinet) to complete unit control circuit.

A pump down cycle should be employed to control all these units. Solenoid valve for the liquid line is an option that

may be supplied loose and should be field installed by others. Room thermostat is supplied and installed by others.

Generally the wiring diagrams will show all electrical components, even those that are

offered as options or should be supplied and installed by others.

Should any component be added to the unit as a field supplied option then the wiring

should follow the given diagram (chart on left / diagrams in Appendix).

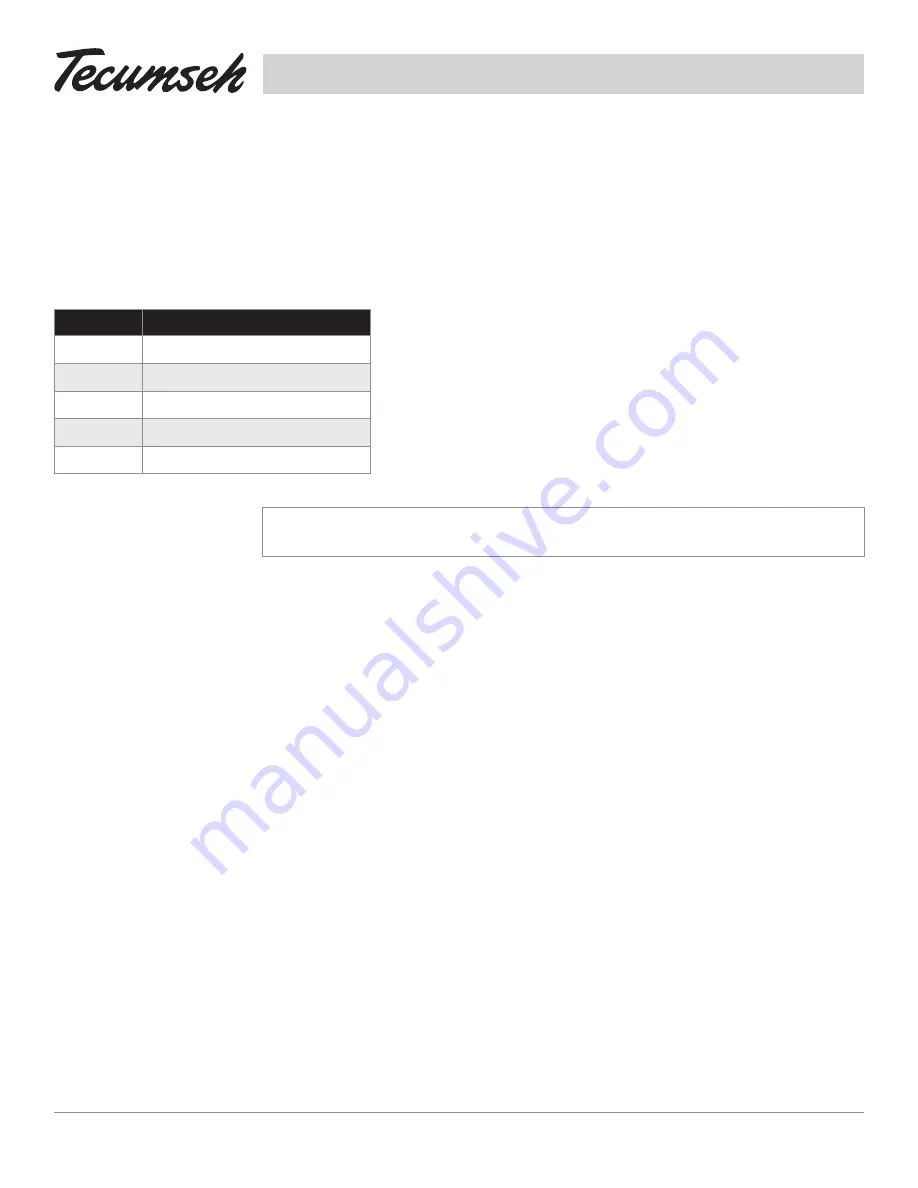

WD Number Description

91292

115V & 208-230V 60 Hz/ 1 Phse, 1 Fan

91293

208-230V 60 Hz/ 1 Phse, 2 Fan

91293-1

200-230V 60 Hz/ 3 Phse, 2 Fan

91294

200-230V 60 Hz/ 3 Phse, 1 Fan

91294-1

208-230V 60 Hz/ 1 Phse, 1 Fan

CAUTION:

Any non-compliance with voltage ranges and phase balances or any altering of electrical

components without Tecumseh written approval will void the warranty.

PIPING

(See Suction and Liquid Line Sizes in Appendix)

Employ only Refrigeration grade copper tubing. Always keep the tubes free of moisture and dirt and remove any

burrs present on the tubes. The thermostatic expansion valve must be the externally equalized type. It can be

mounted inside the unit cooler end compartment. Mount the expansion valve bulb on a horizontal run of suction

line as close as possible to the suction header. Use the clamps provided with the valve to fasten the bulb securely

so there is a tight line-to-line contact between the bulb and the suction line. Suction and liquid connections are

made on the outside of the unit.

Standard piping practices and local/national codes should be employed to size and install refrigerant gas

and liquid lines.

A) The selection of the suction gas line sizes should be guided by the following criteria:

• Assurance of adequate velocity, thus ensuring oil return capability (the tube size must be limited to maintain

velocities no less than 750 fpm for horizontal and down flow and no less then 1500 fpm for up flow)

• Assurance of acceptable pressure drop (The tube size should be limited to maintain pressure drop

no greater than the equivalent of a 2°F temperature drop.)

• Assurance of satisfactory sound level (the tube size should be limited to maintain velocities

no greater than 3000 fpm.)

Horizontal suction lines should be sloped downward in the direction of the compressor at least ½” per 10’ of line.

The appendix tables recommend suction line sizes for installations where the line is horizontal or down flow. In the

event the suction line is up flow, use “one standard size” smaller. A suction trap should be installed at the base of

suction risers. Prefabricated wrought copper traps are available, or a trap can be made by using two street ells and

Содержание Argus

Страница 1: ...Remote Condensing Unit Installation Instructions ...

Страница 35: ...NOTES ...