IST-2237.EC01.01

Istruzione / User’s Manual / Manuel d’utilisation

Pag. 9/20

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI)

Tel. +39 02 26922890 - Fax +39 02 2133734

SE237EN

has a sensor that can detect

Nitric oxide (NO)

gas which is a toxic and colourless,

heavy as air

(

its den-

sity as to air is 1.04

). His

TWA

(

Time-Weighted Average

) and

STEL

(

Short Term Exposure Limit

) are

25

ppm. NO is a strong

oxidant and reacts with combustible and reducing materials. On contact with the air turns it into nitrogen dioxide

(

NO

2

). Nitric oxide is irritating to eyes and respiratory tract. Inhalation can cause pulmonary edema, may also have

effects on the blood, causing the formation of methaemoglobin. In more severe cases it can lead to death. Nitric ox-

ide is a pollutant that is generated in part in combustion processes, in part by natural emissions, fires or civil activi-

ties and industrial processes involving combustion, (

diesel engine, gasoline, LPG, production of heat and electricity etc.

).

SE237EN2

has a sensor that can detect

Nitrogen dioxide (NO

2

)

gas which is a reddish-brown toxic gas with a

characteristic sharp, biting odour,

heavier than air

(

its density has to air is 1.58

). His

TWA

(

Time-Weighted Average

) is 3

ppm and

STEL

(

Short Term Exposure Limit

) is

5 ppm

. NO

2

combined with water turns into nitric acid and nitric oxide.

NO

2

is formed in most combustion processes using air as the oxidant. At elevated temperatures nitrogen combines

with oxygen to form nitrogen dioxide. The most important sources of NO

2

are internal combustion engines (

power

plants, heating and vehicles, especially diesel engines

). NO

2

is toxic by inhalation, it can cause irreversible damage to the

lungs, pulmonary edema and death as it is capable of combining with the haemoglobin by changing the chemical

and physiological, forming methaemoglobin which is no longer able to carry oxygen to the tissues. Also, low con-

centrations (4 ppm) will anesthetize the nose.

SE237EHCL

has a sensor that can detect

Hydrogen chloride (HCL)

(

synonymous with Hydrogen chloride, muriatic acid)

which is normally a liquid, which releases a toxic gas, colourless with a pungent odour,

heavier than air

(

its density

has to air is 1.3

). His

TWA

(

Time-Weighted Average

) is

5 ppm

and

STEL

(

Short Term Exposure Limit

) is

10 ppm

.

This gas, In aqueous solution becomes one of the most corrosive liquids. The vapours are corrosive to eyes, the

skin and the respiratory tract. Inhalation of high gas concentrations may cause pneumonitis and pulmonary edema.

SE237ECL

has a sensor that can detect

Chlorine (CL

2

)

which is a yellow-green gas that has a distinctive strong

odour, is extremely poisonous and

heavier than air

(

its density has to air is 2.5

). His

TWA

(

Time-Weighted Average

) is

0.5

ppm

and

STEL

(

Short Term Exposure Limit

) is

1 ppm

. This gas, In aqueous solution becomes a corrosive acid. The

vapours are corrosive to eyes, skin and the respiratory tract. Inhalation of the gas may cause pneumonitis and

pulmonary edema. Prolonged exposure can cause death.

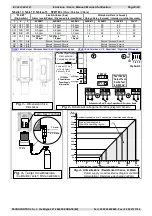

OPERATIONAL DESCRIPTION

The electrochemical sensor is temperature compensated, but is sensitive to extreme humidity variations. The cali-

bration is carried out with specific gas to be detected. Anyway, it can contemporaneously detect other gases that

should be present in the same environment as listed in

tables 3 and 4

.

Preheating

: when powered, the sensor needs a time of preliminary heating of about 60 seconds. During this peri-

od the yellow LED “

FAULT

” flashes. After this period, the yellow LED light off, the green LED “

ON

” illuminates to in-

dicate normal functioning. After this period the unit is able to detect gas even if it attains the optimum stability con-

ditions after about 4 hours continual functioning.

Normal operation

: the green LED “ON” should be light on.

ALARMS:

different alarms levels, depending on the models, can be set by Dip-Switch (

see tables 2 and 5÷11

). There

are two different alarm methods, the normal one, will activate the corresponding relays after a fixed delay, the ad-

vanced one, operate with TLV-TWA, STEL and C value, in this case the relays will activate without delay.

The 1st red Led

(

ALARM 1

) illuminates when the gas concentration attains 1st alarm level. Under normal alarm

method, after about 12 seconds the “

ALARM 1

" relay will activate, while under advanced one, with TLV-TWA level

selected, the relay will activate without delay.

The 2nd red Led

(

ALARM 2

) illuminates when the gas concentration attains 2nd alarm level and after about 30

seconds, the “

ALARM 2

" relay will activate or without delay when TLV-STEL level is selected.

The 3rd red Led

(

ALARM 3

) illuminates when the gas concentration attains 3rd alarm level and after about 60

seconds, the “

ALARM 3

" relay will activate or without delay when TLV-C level is selected.

TLV (

T

hreshold

L

imit

V

alues

)

are defined as an exposure limit to which it is believed nearly all workers can be exposed

day after day for a working lifetime without ill effect.

TLV-TWA (

T

hreshold

L

imit

V

alue–

T

ime-

W

eighted

A

verage

)

is the time-weighted average concentration for a conventional

8-hour workday and a 40-hour workweek, to which it is believed that nearly all workers may be repeatedly exposed,

day after day, without adverse effect.

TLV-STEL

(

T

hreshold

L

imit

V

alue–

S

hort-

T

erm

E

xposure Limit

)

is the concentration to which it is believed that workers can

be exposed continuously for a short period of time without suffering from irritation, chronic or irreversible tissue

damage, or narcosis. STEL is defined as a 15-minute TWA exposure, which should not be exceeded at any time

during a workday.

TLV-C (

T

hreshold

L

imit

V

alue-

C

eiling

)

is the concentration that should not be exceeded during any part of the working exposure.

The values are recommending exposure levels that are protective to workers, OSHA (

O

ccupational

S

afety and

H

ealth

A

dministration

, of the U.S. Department of Labour) and COSHH

(

C

ontrol Of

S

ubstances

H

azardous to

H

ealth in Europe

).

Faults

:

the instrument signal different kind of failures, as listed below. The yellow Led illuminates, the "

S

" output

falls down to 0mA and the “

FAULT

”

normally activated relay deactivate. This relay, if necessary, can be used both to

signal remotely an occurred damage and to signal the absence of power to the instrument.

Yellow Led illuminates each 4 seconds (

with green Led activate

):

this happens when the “

Cartridge Sensor

” has

overcome its theoretical period of life and its correct operation is no longer guaranteed. The detector keeps on op-

erating normally but it is necessary to replace, as soon as possible, the “

Cartridge

” with a new one. The type to be

required is described on

Page 1

. The replacement procedure is described in the attached manual.

Yellow Led activate, green Led off (

FAULT relay activates and 0 mA output signal

):

this signal different kind of faults.

1)

The Dip-Switch set up is wrong, please verify (

see Tables 2 and 5÷11

).

2)

The “

Cartridge

” is not working, please re-