ii

INTRO

Team Losi Racing is continually changing and improving designs; therefore, the actual part may appear slightly different than the illustrated part. Illustrations of parts

and assemblies may be slightly distorted to enhance pertinent details.

TOOLS REQUIRED FOR ASSEMBLY

Team Losi Racing has supplied all necessary Allen wrenches and special wrenches that are needed for assembly and adjustments. The following

common tools will also be required: needle-nose pliers, regular pliers, hobby knife, scissors or other body cutting/trimming tools, and a soldering iron

may be necessary for radio installation. 3/16", 1/4", 5/16" and 11/32" nut drivers are optional.

RADIO/ELECTRONICS

A suggested radio layout is provided in this manual. Your high-performance RC center should be consulted regarding specific questions pertaining to

radio/electrical equipment.

HARDWARE IDENTIFICATION

When in question, use the Hardware Identification Guide at the back of this manual.

For screws, the prefix number designates the thread size and number of threads per inch (e.g., 4-40 is a #4 size thread with 40 threads per inch).

•

The second number, or fraction, designates the length of the screw. For cap head and button head screws, this number refers to the length of the

threaded portion of the screw. For flat head and setscrews, this number refers to the overall length of the screw.

Bearings and bushings are referenced by the inside diameter (I.D.) x outside diameter (O.D.).

•

Shafts and pins are designated by type (Roll, Solid) and referenced by diameter x length.

•

Washers, Spacers and Shims are described by inside diameter or the screw size that will pass through the inside diameter x the thickness or by their

•

designated application (e.g., Ball Stud washer is primarily used under a Ball Stud).

Retaining Clips are sized by the shaft diameter that they attach to or by type (Body). The Hardware Icon associated with E/C-clips only designates

•

the part genre of clips, not the actual part.

Nuts come in four types, Non-Flanged, Flanged (F), Plain and Locking (L) (designated on the Hardware Icons). The prefix number designates the

•

thread size and number of threads per inch. The second number, or fraction, designates the size of the hex. For example, L 4-40 x 1/4" designates a

locknut that will thread onto a 4-40 screw using a 1/4" nut driver.

Setscrews come in three types, Cup (C), Flat (F) and Oval (O) (designated on the hardware Icons). The prefix number designates the thread size and

•

number of thread per inch. The second number, or fraction, designates the length of the threaded portion of the screw.

TABLE OF CONTENTS

SECTIONS

1.

INTRODUCTION

......................................................

i

Vehicle/Manual Organization ............................

i

Important Safety Notes ......................................

i

Tools Required for Assembly ............................

ii

Radio/Electronics ..............................................

ii

Hardware Identification

....................................

ii

2.

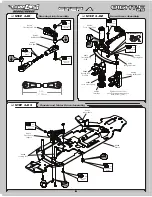

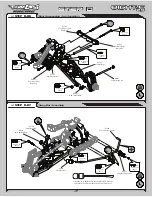

Step A:

Steering Assembly .................................. 1-2

3.

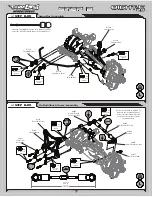

Step B:

Front Clip ............................................... 3-8

4.

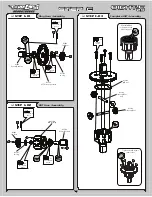

Step C:

Center Transmission ............................. 9-11

5.

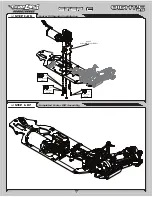

Step D:

Rear Clip ............................................ 12-17

TABLES

Table 1:

8IGHT-E 2.0

Completed Vehicle Specifications

ii

Table 2:

Servo Installation .................................................. 21

8IGHT-E 2.0 COMPLETED KIT SPECIFICATIONS

Note: Final vehicle weight will vary depending on accessories used.

*All measurements taken at ride height (32mm).

Overall Chassis Length: 16.35" (415mm)

Wheelbase: 12.71"-12.87" (323-327mm)

*Front Track Width: 12.13" (308mm)

Overall Length w/Tires: 19.5" (497mm)

*Overall Height: 6.625" (168mm)

*Rear Track Width: 12.13" (308mm)

Table 1: 8IGHT-E 2.0 Completed Vehicle Specifications.

6.

Step E:

Shocks ................................................ 18-20

7.

Step F:

Radio Tray .......................................... 21-24

8.

Step G:

Tire and Wheel Installation ................ 25-26

9.

Checklist Before Your First Run

........................27

10.

Setup Guide

.................................................... 28-29

11.

Warranty Information

................................... 30-31

12.

Blank 8IGHT-E 2.0 Setup Sheet

.........................32

13.

Hardware Identification Guide

...........................33

14.

Filled-out 8IGHT-E 2.0 Vehicle Setup Sheet

......34

Vehicle/Manual Organization:

The vehicle is composed of different steps marked A through H. Each step contains all of the parts necessary to complete a particular section of the

vehicle. Some of these steps have sub-assembly steps within them. It is helpful to read through the instructions for an entire step prior to working on

your vehicle. Next to each of the step numbers is a check box. At the completion of each step, place a check in this box so that if you must stop and

come back to the assembly, you will be able to pick up where you left off.

For your convenience, an actual-size Hardware Identification Guide is included as a fold-out page at the back of this

manual. Hardware that is not easily differentiable in each step is called out with an icon which contains a small picture

of the part genre (referenced on the Hardware Identification Guide), the quantity of that part required for what is

shown in the step, and the size or name of that part. To check a part, hold it against the silhouette until the correct part

is identified. Associated with each of these parts, in the Hardware Identification Guide, is an LOSA-Number which is used when ordering replacement

parts for your 8IGHT-E 2.0. In some cases, extra hardware has been supplied for parts that may be easy to lose.

Components used in each step are identified by their relative LOSA-Number and the component’s name. With the exception of a few parts, these are

not referenced in the Hardware Identification Guide.

The molded parts in Team Losi Racing vehicles are manufactured to demanding tolerances. When screws are tightened to the point of being snug, the

parts are held firmly in place. For this reason, it is very important that screws not be overtightened in any of the plastic parts.

In some steps there will be a filled black circle with a white number. These indicate the specific order by which assembly must occur. In cases where

steps are repeated (front/rear or left/right) these numbers may be omitted. Please note that these numbers will not call out every sub-step required for

the step’s assembly procedures, they will only highlight the critical order required for assembly.

In each step, there are specific “Detail Icons” (shaped like a stop sign) that call out critical precautions or assembly tips for the process. There is a

reference key that describes the meaning of each of the icons located on the fold-out Hardware Identification Guide at the back of this manual.

To ensure that parts are not lost during construction, it is recommended that you work over a towel or mat to prevent parts from rolling away.