6

7

2.2

Cleaning the Label Sensor

1

5

2

4

2

3

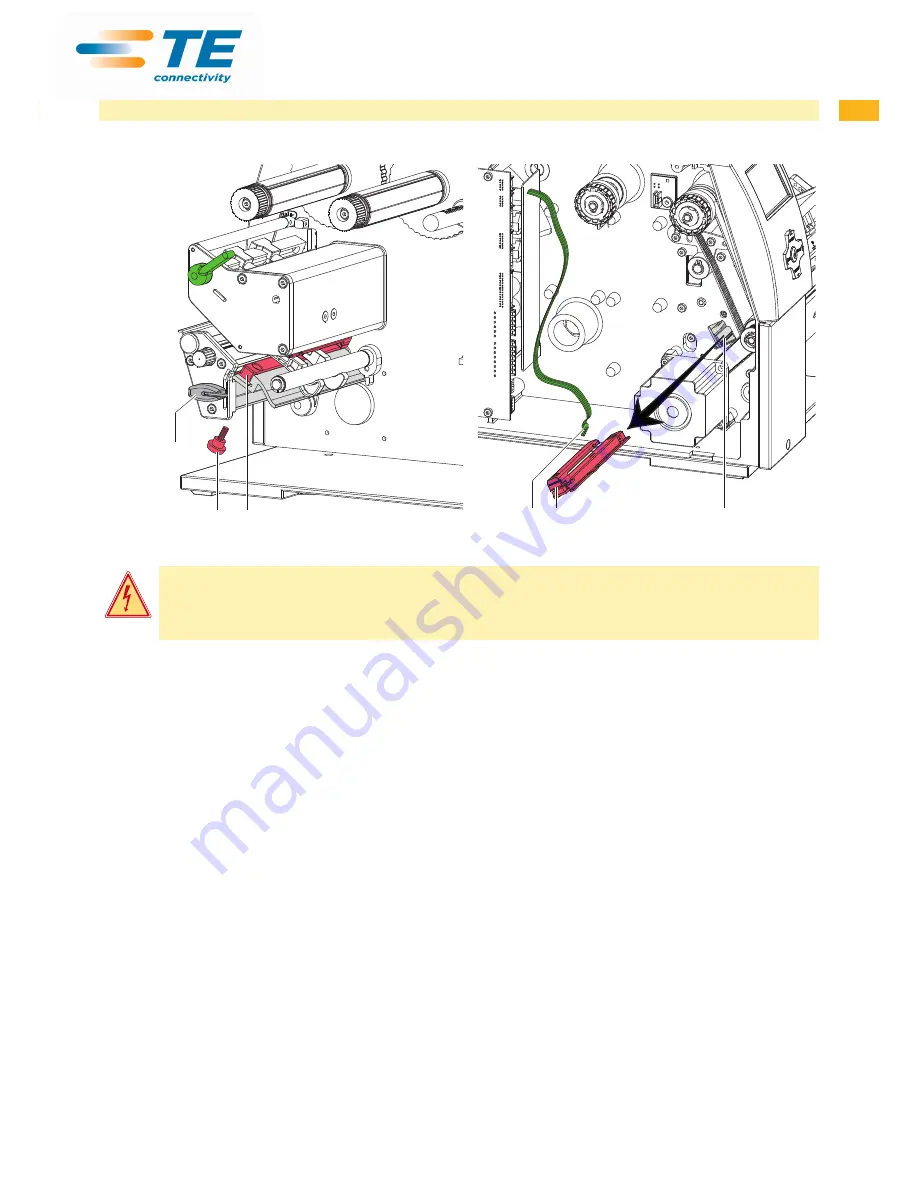

Fig. 1

Cleaning the label sensor

Fig 2

Removing the label sensor

Danger!

Risk of death via electric shock!

X

Before opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

1. Remove media from the printer.

2. Remove the Allen key (5) from its retainer.

3. Remove the rear cover of the printer.

4. Unscrew knurled thumb screw (1).

5. Unplug the cable (3) from the plug on the rear end of the label sensor (2).

6.

Push the label sensor (2) so deep as possible into the guide profile toward the chassis.

7. Slide out the label sensor assembly (2) toward the back side cover.

8. Clean label sensor and sensor units (2) with brush or cotton swab soaked in pure alcohol.

9. Push label sensor back toward the print head side of printer so you can see the hole in the label sensor over the

long hole in the profile (guide).

10. Connect the cable (3) to the label sensor (2).

11. Attach knurled thumb screw (1).

12. Pull the label sensor (2) via knurled thumb screw (1) so far as possible toward cover side. This prevents the cable

(3) from being pinched when installing the rear cover.

13. Install the rear cover of the printer.

14. Adjust label sensor

operators manual.

15. Insert the Allen key (5) into its retainer.

2 Cleaning