114-13233

Rev B

11

of 13

DANGER

Consideration must be given to toxicity and other safety requirements recommended by the solvent manufacturer. Refer to the

manufacturer's Material Safety Data Sheet (MSDS) for characteristics and handling of cleaners. Trichloroethylene and

Methylene Chloride can be used with no harmful effect to the connectors; however TE does not recommend them because of

the harmful occupational and environmental effects. Both are carcinogenic (cancer-causing) and Trichloroethylene is harmful

to the earth's ozone layer.

NOTE

If you have a particular solvent that is not listed, contact the Tooling Assistance Center or Product Information number at the

bottom of page 1.

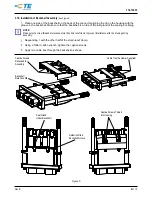

CLEANER

TIME

(Minutes)

TEMPERATURE

(Max)

NAME

TYPE

ALPHA 2110

Aqueous

1

132°C [270°F]

BIOACT EC-7

Solvent

5

100°C [212°F]

Butyl CARBITOL

Solvent

1

Ambient Room

Isopropyl Alcohol

Solvent

5

100°C [212°F]

KESTER 5778

Aqueous

KESTER 5779

Aqueous

LONCOTERGE 520

Aqueous

LONCOTERGE 530

Aqueous

Terpene

Solvent

Figure 13

C.

Drying

When drying cleaned connectors, make certain that temperature limitations are not exceeded: -40° to

105° C [-40° to 221°F]. Excessive temperatures may cause degradation.

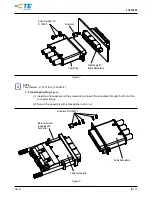

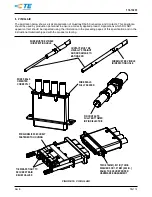

3.17.

Checking Installed Connector

All solder joints should conform to those specified in Test Specification 109-11. The connector must seat on the

pc board to within the tolerance of 0-0.25 mm [.000-.010 in.].

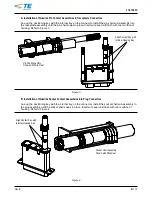

3.18.

Panel Cutouts

Recommended panel cutout is shown in Figure 14. Panel thickness range is 1.52-1.65 mm [.060-.065 in.].

Figure 14

3.19.

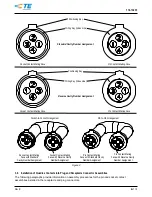

Mating/Unmating

To properly mate and unmate the two halves of a connector system, align the keystone keying and fully mate

the connectors. Engage and tighten the retainer screws/jack screws to 0.40-0.45 Nm [3.5-4.0 in.-lbs] to ensure

the seal is compressed and the shells are bottomed.

ALPHA, BIOACT, CARBITOL, LONCOTERGE, and KESTER are trademarks of their respective owners.

10

°

±2

°

3.05 ±0.05

[.120 ±.002]

2 Plc

R 3.35 [.132] 4 Plc

11.40 [.449]

47.04 [1.852]

42.52 1.674]