408-10040

Rev

G

9

of 12

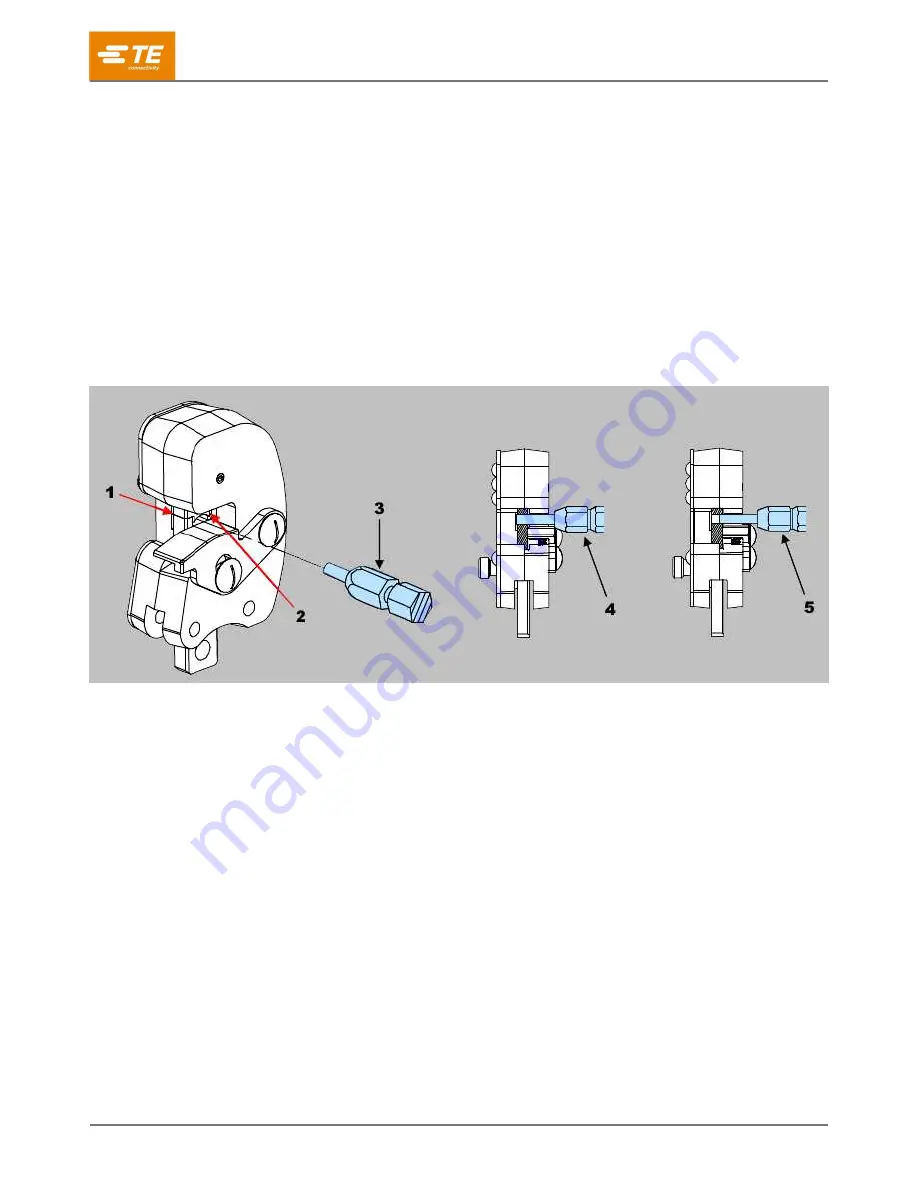

To gage die closure, complete the following steps.

1. Remove traces of oil or dirt from the crimping chamber and plug gage.

2. Close the tool handles until the wire barrel dies are bottomed. Do not apply additional pressure to the

tool handles.

3. With wire barrel dies bottomed, inspect the wire barrel crimp die closure using the proper plug gage.

Press the spring-loaded locator down and hold the gage in alignment with the die closure.

4. Align the GO element with the wire barrel section of the crimping chamber (Figure 8). Push the element

straight into the crimping chamber without using force. The GO element must pass completely through

the crimping chamber.

5. Align the NO-GO element and try to insert it straight into the same section of the crimping chamber.

The NO-GO element can start entry, but must not pass completely through the crimping chamber

(Figure 8).

Figure 8: Inspecting the wire barrel crimping dies

1

Wire barrel dies are

bottomed, but not under pressure

2

Insert 0.025 mm [.001 in.] shim

3

Gage

4

GO gage must pass completely through the die closure

5

NO GO gage can enter partially, but must not pass completely through the die closure