408-6810

3 of 4

Rev A

4.2. Periodic Inspection

Regular inspections should be performed by quality

control personnel. A record of scheduled inspections

should remain with the tool and/or be supplied to

supervisory personnel responsible for the tool. Though

recommendations call for at least one inspection a

month, the inspection frequency should be based on

the amount of use, ambient working conditions,

operator training and skill, and established company

standards. These inspections should be performed in

the following sequence:

A. Visual Inspection

1. Remove all lubrication and accumulated film by

immersing the tool (handles partially closed) in a

suitable commercial degreaser that will not affect

paint or plastic material.

2. Make certain all retaining pins are in place and

secured with retaining rings. If replacements are

necessary, refer to the parts list in Figure 4.

3. Close the tool handles until the ratchet releases,

then allow handles to open freely. If they do not

open quickly and fully, the spring is defective and

must be replaced (see Section 5, REPAIR).

4. Inspect the head assembly, with special

emphasis on checking for worn, cracked, or broken

jaws. If damage to any part of the head assembly is

evident, the tool must be repaired (see Section 5,

REPAIR).

B. Crimp Height Inspection

Crimp height inspection is performed through the use

of a micrometer with a modified anvil, commonly

referred to as a crimp-height comparator. TE does not

manufacture or market crimp-height comparators.

Detailed information on obtaining and using crimp-

height comparators can be found in Instruction Sheet

408-7424.

Proceed as follows:

1. Refer to the table in Figure 1, and select a contact

and a wire (maximum size) for each crimp section

listed in the table.

2. Refer to Section 3, CRIMPING PROCEDURE,

and crimp the contact(s) accordingly.

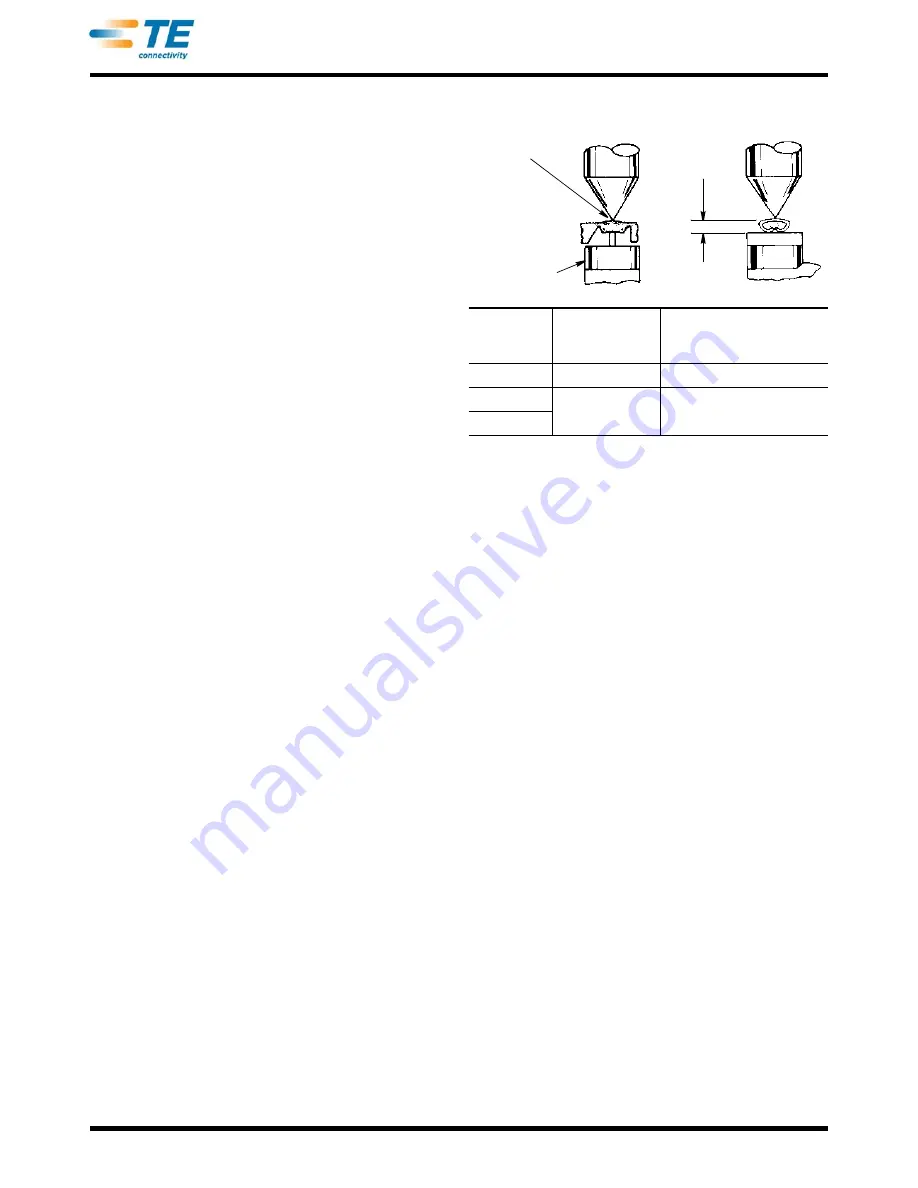

3. Using a crimp height comparator, measure wire

barrel crimp height as shown in Figure 3. If the

crimp height conforms to that shown in the table,

the tool is considered dimensionally correct. If not,

the tool must be repaired (see Section 5, REPAIR).

C. Ratchet Inspection

Obtain a 0.03-mm [.001-in.] shim that is suitable for

checking the clearance between the bottoming

surfaces of the crimping jaws.

Proceed as follows:

Figure 3

1. Select a contact and wire (maximum size) for the

tool (see Figure 1).

2. Position the contact and wire between the

crimping jaws, according to Section 3, CRIMPING

PROCEDURE (Steps 1 through 4). Holding the wire

in place, squeeze the tool handles together until the

ratchet releases. Hold the tool handles in this

position, maintaining just enough pressure to keep

the jaws closed.

3. Check clearance between the bottoming surfaces

of the crimping jaws. If the clearance is 0.03 mm

[.001 in.] or less, the ratchet is satisfactory. If

clearance exceeds 0.03 mm [.001 in.], the ratchet is

out of adjustment and must be repaired (see

Section 5, REPAIR).

If the tool conforms to these inspection procedures,

lubricate it with a THIN coat of any good SAE No. 20

motor oil and return it to service.

5. REPAIR

All parts of the tool can be replaced. Customer

replaceable parts are listed in Figure 4. A complete

inventory should be stocked and controlled to prevent

lost time when replacement of parts is necessary. If

parts that affect ratchet setting are replaced, the

ratchet must be adjusted using the spanner wrench

(see Figure 4).

Proceed as follows:

1. Loosen the ratchet nut on the back of tool (side

with wire size markings).

2. Check bottoming of tool jaws according to

Paragraph 4.2.C, Ratchet Inspection. Turn screw on

front of tool CLOCKWISE to tighten ratchet or

COUNTERCLOCKWISE to loosen ratchet.

WIRE SIZE

(AWG) MAX

CRIMP

SECTION (WIRE

SIZE MARKING)

CIRMP HEIGHT

(DIM. “A”)

20

24-20

1.14 ±0.08[.045 ±.003]

16

18-16

14

1.588 ±0.089 [.0625 ±.0035]

14

Position Point on

Center of Wire Barrel

Opposite Seam

Modified Anvil

“A”