AN-000158

Document Number: AN-000158

Page 17 of 22

Revision: 1.2

Sensor Configuration

Max Assembly Force (grams-force)

Max Allowable Frequency Shift Due to

Assembly (Hz)

Pulse-Catch

50

750

Pitch-Echo

150

1500

Table 6. Summary of maximum allowable residual assembly force.

The easiest way to detect when this force is exceeded is to measure the frequency shift from before and after assembly.

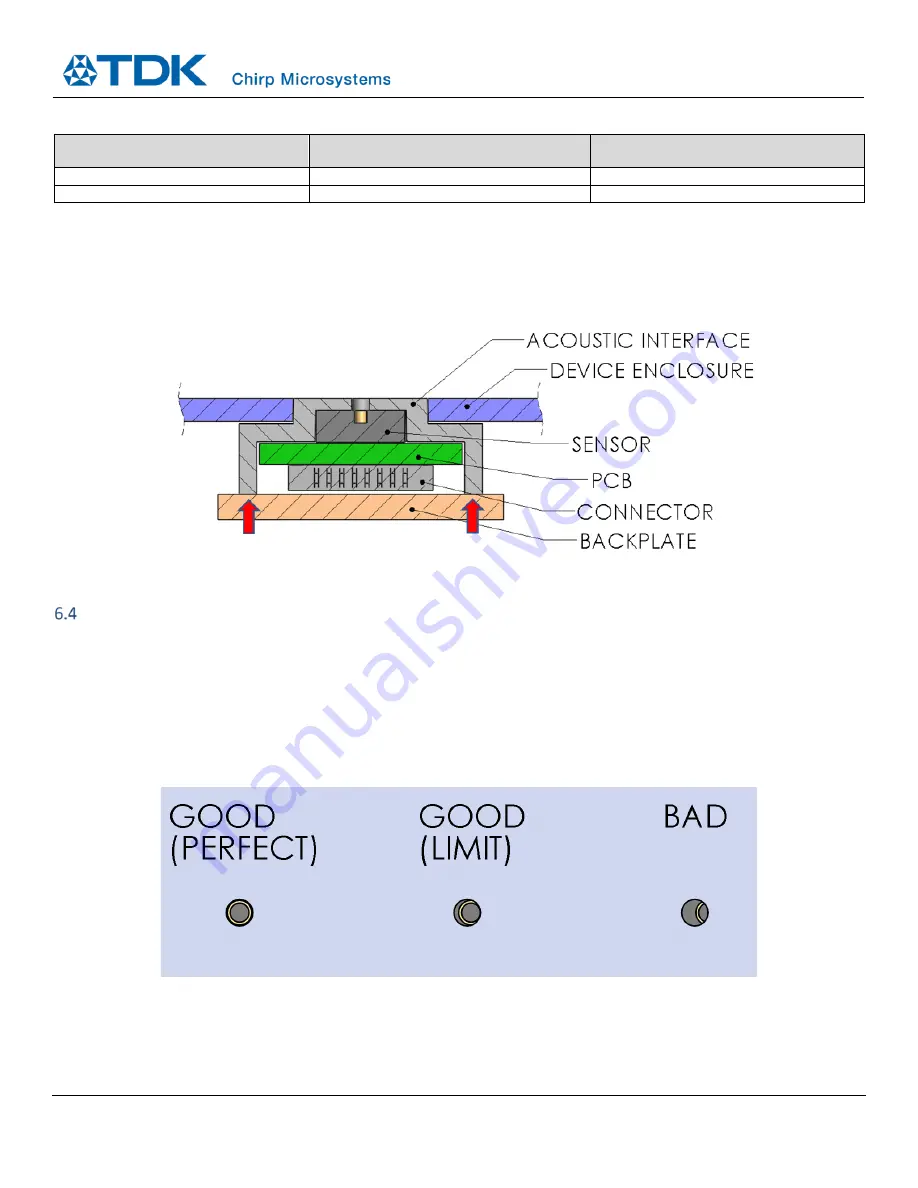

One method of holding the module against the device enclosure while avoiding applying excessive force on the module is to use a

backplate to transfer the force applied to the module to the Acoustic Interface instead of the sensor (see Figure 16).

Figure 16. Example of a backplate-based module design to avoid applying excessive force on the sensor.

SENSOR-TO-ACOUSTIC INTERFACE ASSEMBLY TOLERANCES

When assembling the sensor and Acoustic Interface together, Chirp recommends the sensor port hole be concentrically aligned to

Acoustic Interface to within 0.1 mm or better. The sensor port should not be blocked or occluded by the Acoustic Interface (see

Figure 17).

For the Z-dimension assembly tolerance, the only requirement is that there is no gap between the sensor and the Acoustic Interface

and that their mating surfaces are parallel (see Figure 18). Any gap between the sensor and Acoustic Interface will result in

unpredictable acoustic performance. In addition, while ensuring no gap between the sensor and Acoustic Interface, the assembly

force must be below the maximum force limit as discussed in Section 6.3.

Figure 17. Examples of various degrees of sensor port alignment with the Acoustic Interface, from perfect concentric alignment (left), maximum

acceptable limit tangent alignment (middle), to bad occluded alignment (right).