TB Wood’s • 888-829-6637

P-5071-TBW • Form 885D

3

To Remove:

1.

Loosen and remove all of the cap screws from the idler assembly.

2. Insert the cap screws into the tapped holes in the mating hub. Evenly and progressively tighten the

cap screws until the idler bushing and mating hub separate.

3. Remove idler assembly from the mounting structure.

Replacement Parts:

Following is a list of the replacement bearings.

SH-BB

G275

SD-BB

G275

SK-BB

G276

SF-BB

G276

E-BB

G277

Bushing

Replacement

Size

Bearings

(2 per unit)

3

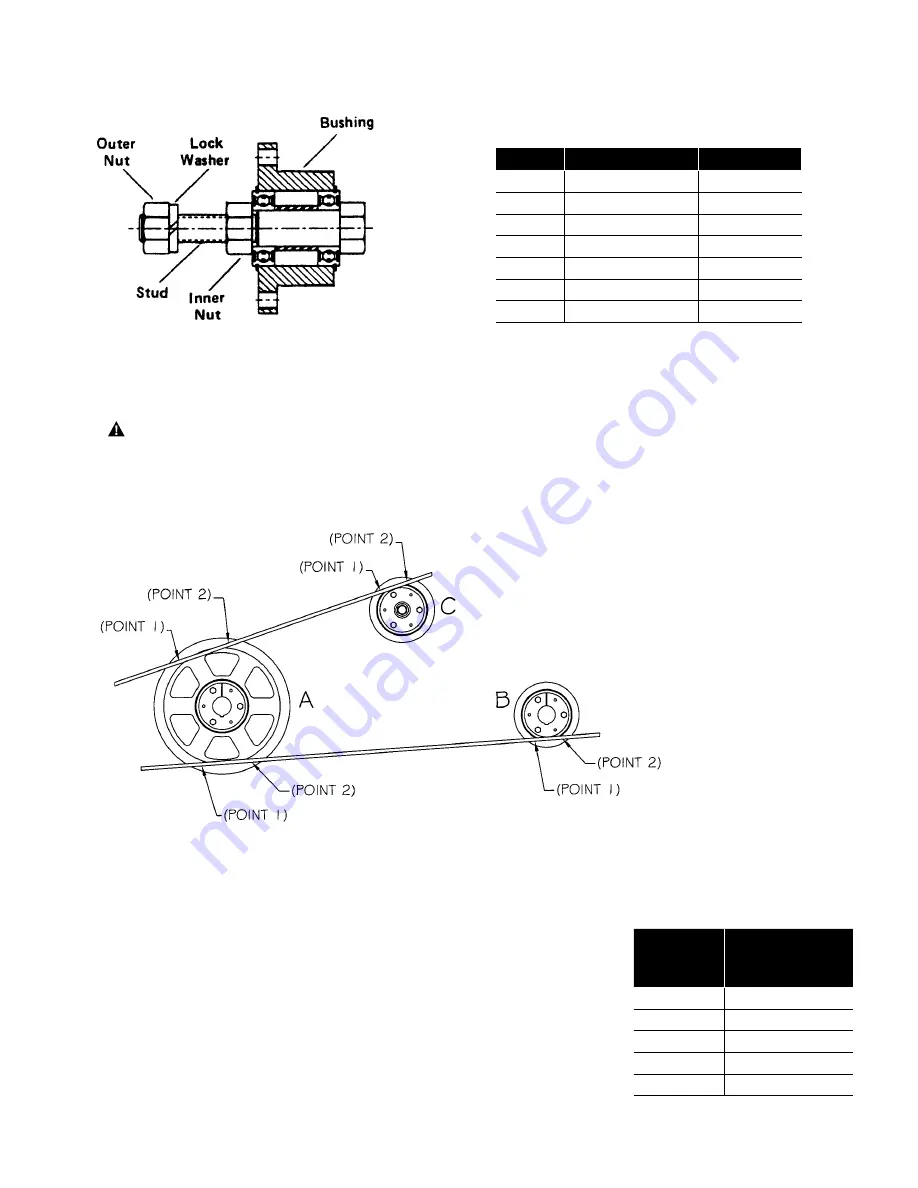

. Mount the assembly to the mounting structure. Place lockwasher and then outer nut on idler bushing

stud, Figure 2. Using a torque wrench, tighten the outer nut to the value listed in Table 2.

Note:

If the assembly will be threaded into a tapped hole in the mounting surface, extreme care

should be used to prevent the inner nut from turning against the bearings. Additional tightening force

on inner nut will cause bearings to fail prematurely.

WARNING

The inner nut has been tightened to 5 ft. lbs. DO NOT tamper with or retighten

above this value or the bearings will fail prematurely.

4. Make sure idler assembly is parallel with both the driveR and driveN shaft. Properly align the driveR,

driveN, and idler assembly by the four-point method illustrated in Figure 3, below.

SH-BB

1/2-13NC

60 ft. lb.

SD-BB

1/2-13NC

60 ft. lb.

SD-BB58

5/8-11NC

125 ft. lb.

SK-BB

3/4-10NC

225 ft. lb.

SF-BB

3/4-10NC

225 ft. lb.

SF-BB1

1-8NC

300 ft. lb.

E-BB

1 3/8-8NC

750 ft. lb.

Idler

Cap Screw

Torque

Table 2 – Outer Nut Tightening Torque

Note: The inner nut torque should not

exceed 5 ft. lbs. when reassembling.

Note: Straight edge must touch

two points on A and two points

on B and C.

Figure 3

Figure 2

3. Mount the assembly to the mounting structure. Place lockwasher and then outer nut on idler bushing stud,

Figure 2. Using a torque wrench, tighten the outer nut to the value listed in Table 2.

Note

: If the assembly will be threaded into a tapped hole in the mounting surface, extreme care should be

used to prevent the inner nut from turning against the bearings. Additional tightening force on inner nut will

cause bearings to fail prematurely.

WARNING: The inner nut has been tightened to 5 ft. lbs. DO NOT tamper with or retighten

above this value or the bearings will fail prematurely.

4. Make sure idler assembly is parallel with both the driveR and driveN shaft. Properly align the driveR,

driveN, and idler assembly by the four-point method illustrated in Figure 3, below.

To Remove:

1. Loosen and remove all of the cap screws from the idler assembly.

2. Insert the cap screws into the tapped holes in the mating hub. Evenly and progressively tighten the cap

screws until the idler bushing and mating hub separate.

3. Remove idler assembly from the mounting structure.

Replacement Parts:

Following is a list of the replacement bearings.

Note:

The inner nut torque should not exceed 5 ft. lbs. when reassembling.

To Remove:

1.

Loosen and remove all of the cap screws from the idler assembly.

2. Insert the cap screws into the tapped holes in the mating hub. Evenly and progressively tighten the

cap screws until the idler bushing and mating hub separate.

3. Remove idler assembly from the mounting structure.

Replacement Parts:

Following is a list of the replacement bearings.

SH-BB

G275

SD-BB

G275

SK-BB

G276

SF-BB

G276

E-BB

G277

Bushing

Replacement

Size

Bearings

(2 per unit)

3

. Mount the assembly to the mounting structure. Place lockwasher and then outer nut on idler bushing

stud, Figure 2. Using a torque wrench, tighten the outer nut to the value listed in Table 2.

Note:

If the assembly will be threaded into a tapped hole in the mounting surface, extreme care

should be used to prevent the inner nut from turning against the bearings. Additional tightening force

on inner nut will cause bearings to fail prematurely.

WARNING

The inner nut has been tightened to 5 ft. lbs. DO NOT tamper with or retighten

above this value or the bearings will fail prematurely.

4. Make sure idler assembly is parallel with both the driveR and driveN shaft. Properly align the driveR,

driveN, and idler assembly by the four-point method illustrated in Figure 3, below.

SH-BB

1/2-13NC

60 ft. lb.

SD-BB

1/2-13NC

60 ft. lb.

SD-BB58

5/8-11NC

125 ft. lb.

SK-BB

3/4-10NC

225 ft. lb.

SF-BB

3/4-10NC

225 ft. lb.

SF-BB1

1-8NC

300 ft. lb.

E-BB

1 3/8-8NC

750 ft. lb.

Idler

Cap Screw

Torque

Table 2 – Outer Nut Tightening Torque

Note: The inner nut torque should not

exceed 5 ft. lbs. when reassembling.

Note: Straight edge must touch

two points on A and two points

on B and C.

Figure 3

Figure 2

Note

: Straight edge must

touch two points on A and two

points on B and C.

Figure 3

Figure 2

Table 2

–

Outer Nut Tightening Torque

Idler

Cap Screw

Torque

SH-BB

1/2-13NC

60 ft. lb.

SD-BB

1/2-13NC

60 ft. lb.

SD-BB

58 5/8-11NC

125 ft. lb.

SK-BB

3/4-10NC

225 ft. lb.

SF-BB

3/4-10NC

225 ft. lb.

SF-BB1

1-8NC

300 ft. lb.

E-BB 1

3/8-8NC

750 ft. lb.

Bushing

Size

Replacement

Bearings

(2 per unit)

SH-BB

G275

SD-BB

G275

SK-BB

G276

SF-BB

G276

E-BB

G277