5. Maintenance and inspection

IOM manual

–

SF & SFA series

28

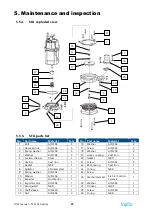

5.5.6.

SFA disassembly procedure

NOTICE:

➢

Before disassembling, make sure to drain the oil from the pump.

➢

Mechanical seal should be replaced only when broken or worn (see chapter

5.4.

Oil inspection and change

).

1. Strainer [2] disassembly

Remove the screw [1] to remove the strainer [2].

2. Pump casing [5] disassembly

Remove the screw [3] and spring washer [4] to remove the pump cover [5] and the gasket

[6].

3. Impeller [10] disassembly

Remove agitator [7], spring washer [8], and washer [9]; then remove the impeller [10],

impeller adjusting shim [11], shaft sleeve [13] and the sand guard [12].

4. Back casing [21] and mechanical seal [24] disassembly

After removing the screw [20], remove the back casing [21] (when doing this, be careful

not to damage sealing face of the mechanical seal [24]), casing O-ring [22] and gasket

[17]. Remove the mechanical seal from the main shaft.

NOTICE:

Mechanical seal replacement must be handled by the qualified staff, contact

Tapflo for more information.

5.5.7.

Reassembly procedure

1. For reassembly procedure follow the disassembly procedure in reverse sequence.

Nevertheless there are a few things that you have to remember in order to assemble the

pump correctly.

NOTICE:

➢

The gaskets and O-rings must be replaced with new ones. Also replace any parts that

are worn or damaged.

➢

After complete reassemble, keep in mind to pour the specified amount of oil into the

pump.

2. Wipe and degrease the mechanical seal sealing faces. Lubricate the outer circumference

of the mechanical seal to facilitate insertion.

NOTICE:

➢

For further details on how to install the mechanical seal, refer to the "Mechanical seal

assembly procedure" that comes with the mechanical seal that is sold separately as a

spare part.

➢

For cleaning use dust-free material e.g. blue towel TORK 1230081.

3. After complete reassemble check that the impeller rotates smoothly and that it does not

come in contact with the suction cover.

4. To make sure that the pump operates normally, perform a trial operation before placing

the pump back into service.