51

INSTALLATION INSTRUCTIONS

Gas Supply (cont.)

Gas Supply

Gas Piping

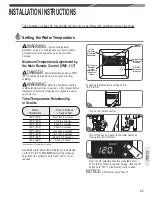

Pipe-Sizing Procedure – Example

The gas supply system must be properly sized to ensure

the proper operation of this tankless water heater as

well as all the gas appliances on the system. Failure to

ensure the gas system, (meter, regulators, and piping) are

properly sized could result in improper operation of this

or other gas appliances. Insufficient gas pressure/supply

can cause pilot outages, lockouts, or operating conditions

that could lead to an appliance failure, improper combus-

tion, carbon monoxide, sooting, or fire. Gas line sizing is

based on gas type, the pressure drop in the system, the

gas pressure supplied, and the gas line type. For gas pipe

sizing in the United States, refer to the National Fuel Gas

Code, (NFPA 54, ANSI Z223.1). For Canadian gas pipe siz-

ing, refer to the Natural Gas and Propane Installation Code

CAN/CSA B149.1.

These simplified instructions only address low pressure

gas systems using Schedule 40 Metallic Pipe (Black

Iron). For hybrid gas systems, high pressure main lines

with regulators at the appliances, gas systems piped with

corrugated stainless steel tubing (CSST), or Propane gas

systems.

Determining the required regulator and

gas meter size.

Find the BTU capacity of each appliance on the system.

This information is located on a rating label attached to

the appliance. Total the BTU of all the appliances together

and divide that by the heating value of the fuel (for natural

gas the average is 1,024 or 2,546 for propane). This will

give you the total cubic feet per hour of gas required for

the system.

At your gas meter/regulator there will be a rating plate

that gives the cubic feet per hour capacity of that equip-

ment. If the total gas required for the system is greater

than the rating of the meter/regulator then the local gas

company will need to be contacted in order to upgrade the

meter/regulator for the system.

Gas Input of

Cubic Feet Water Heater (BTU/HR)

Per Hour (CFH) = Heating Value of Gas (BTU/FT

3

)

Determining the required pipe size.

The gas system is designed to operate at a certain maxi-

mum pressure drop. A pressure drop greater than what

is permissible can cause operational issues with the gas

appliances. The National Fuel Gas Code (NFPA 54, ANSI

Z223.1 2012) allows for three pressure drop levels, a 0.3

inch W.C., (see table 2); a 0.5 inch W.C., (see table 3) and

a 3.0 inch W.C., (see table 4) pressure drop for natural

gas. Only a 0.5 inch W.C. pressure drop is allowable with

Propane (see table 5). For Canadian installations the

maximum allowable pressure drop is 0.5 inch W.C., (see

table 3).

Measure the inlet gas pressure to the system using a ma-

nometer. For Natural Gas, if the inlet pressure is less than

8.0 inches W.C. then use Table 2 or 3 for your gas pipe

sizing. Table 4 can only be used if the inlet gas pressure

is 8.0 inches W.C. or greater. Table 4 cannot be used for

Canadian installations.

The gas piping system consists of a main trunk line that

runs from the meter/regulator and branch lines that run

from the trunk line to the individual appliances. A branch

may carry gas for more than one appliance.

The trunk line must be sized to carry the entire load of all

the gas appliances on the system. As with determining

the meter/regulator size, total the BTU of all the appli-

ances together and divide that by the heating value of

the fuel (for natural gas the average is 1,024 or 2,546 for

propane). This will give you the total cubic feet per hour

of gas required for the trunk line. Measure the total length

of the line Refer to Table(s) 2, 3, or 4 and find the number

closest to but higher than the total cubic feet per hour

requirement calculation. This will tell you the minimum

size that the trunk line must be.

Each branch line must be sized to carry the load of the

appliance(s) attached to it. If more than one appliance is

on a branch total the BTU and as with the trunk line divide

that by the heating value of the fuel. Refer to Table(s) 2,

3, or 4 and find the number closest to but higher than the

total cubic feet per hour requirement calculation for the

branch and appliance(s). This will tell you the minimum

size for that branch line and appliance.