S e t ti n g

11

Materials of Cap Used

For the salon service using the hot double‑process perming agents or the acidic hair dyes (acidic color), use the polyethylene cap.

Since the polyethylene cap can transmit infrared rays, the infrared thermal sensor can correctly measure the hair temperature,

thereby enabling correct temperature control.

If any part of the customer s body or clothes is caught between the main unit and the ring of the Roller Ball during operation,

the rotation clutch mechanism of the ring will work to stop rotation and prevent danger.

Safe Rotation Function of Ring

The use of caps, except those made of polyethylene, may cause abnormal temperature increases.

When such caps are used, be sure to use the product in manual mode.

If the head of the customer is misaligned from the beginning of the operation, an alarm will sound about

three minutes after initiation of operation, and the error code will be displayed.

5cm

24

cm

12

cm

If the customer feels sick while using the Roller Ball, immediately stop using the product.

The far infrared rays from the Roller Ball will not affect the human body at all, but the customer may feel sick

due to the heat if the customer is in poor health condition.

CAUTION

Ap

pro

x.

A

pp

ro

x.

( )

CAUTION

Be sure to observe the correct use to make the maximum performance of the Roller Ball and to

ensure comfortable use by the customer.

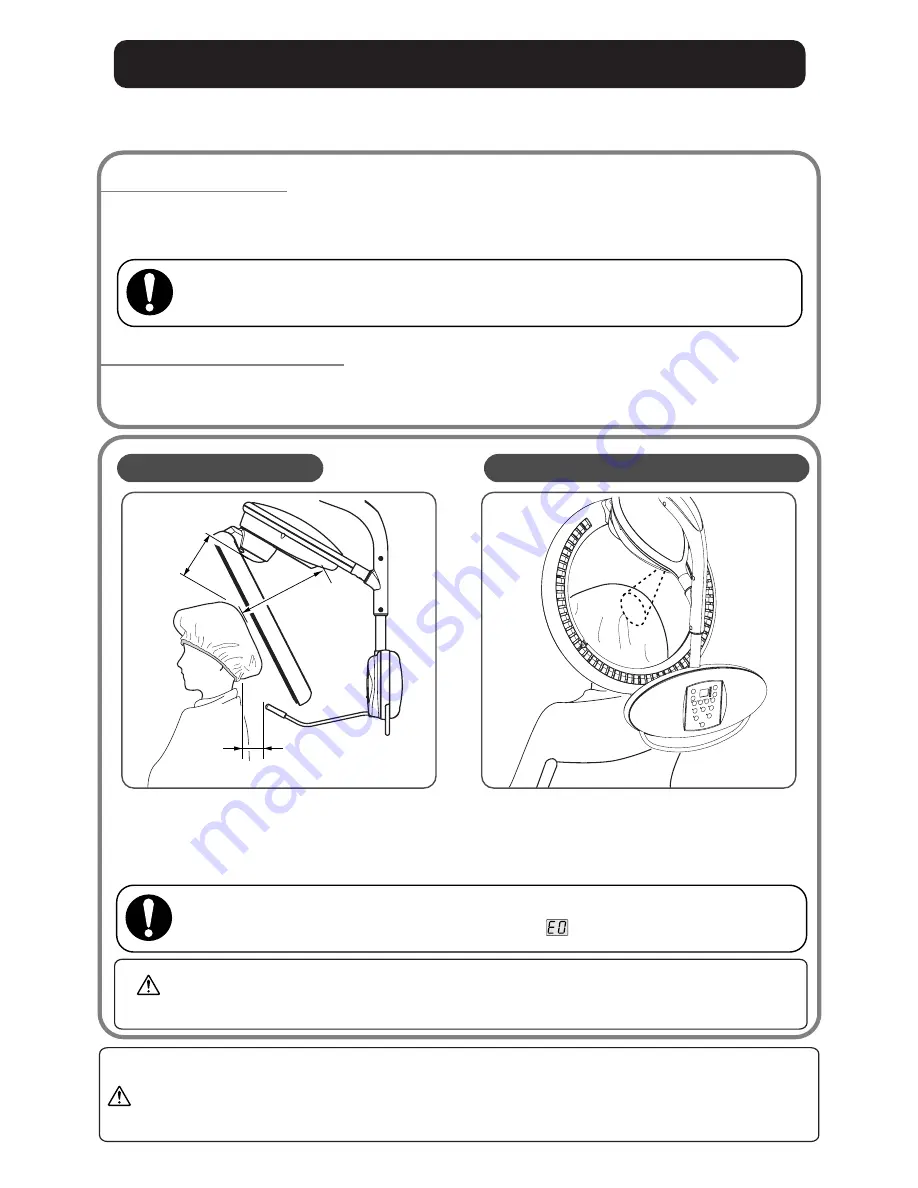

Correct Setting Position

Setting the Roller Ball in Correct Position

Place the top of the head approximately 12 cm away from the

pivot of the ring and approximately 24 cm away from the

infrared thermal sensor.

(Approximately 5 cm between the nape guard and the nape).

Position the nape guard 5 cm away from the customer's nape

and set it at the center of the nape.

Move the chair up or down according to the seating height

of the customer or move the Roller Ball main unit up or down

to adjust the height.

When setting the product, be careful that the product and the dryer arm do not contact the

surrounding equipment or personnel. Furthermore, when moving the product, be sure to hold it by

the grip; move the product slowly and carefully. Failure to heed this warning may lead to breakage

of the product resulting in burns.

Approx.