Trouble examples and Corrective actions

202

Chapter 9

PT10

2-2.

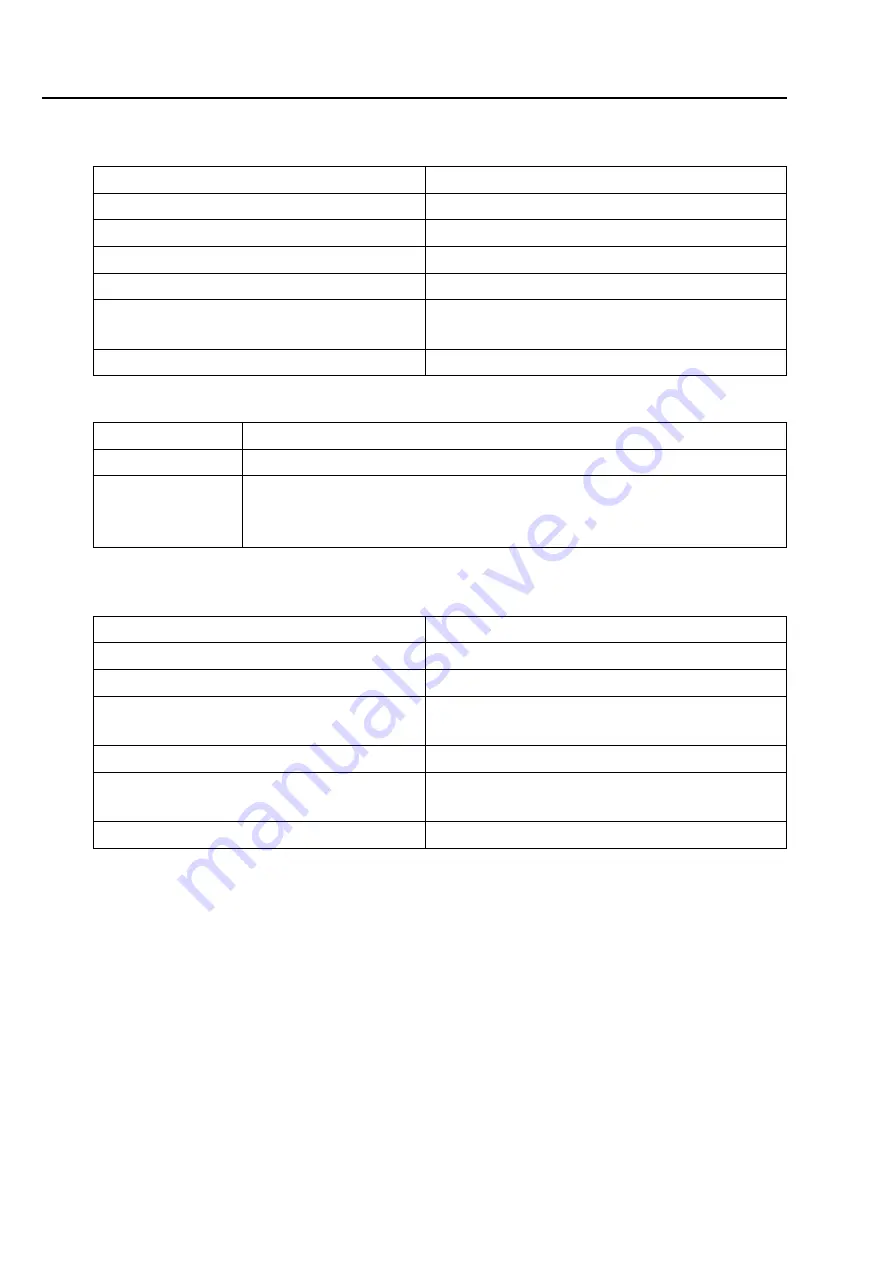

Needle breaks.

If the followings seem to cause the trouble, please ask the distributor for information.

2-3.

Bad finishing of sewing

If the followings seem to cause the trouble, please ask the distributor for information.

There is a play on the fringe of frame.

Abrasion and breakage of neighboring parts of take-up lever drive and needle bar drive.

Bad take-up lever timing.

Belt tension of drive system is too strong or too weak.

Belt tension of drive system is too strong or too weak.

Setting for the machine does not match embroidery condition.

Cause

Troubleshooting

Bad thread tension

Adjust tension.

Density of design data is very high.

Correct data. Delete unnecessary underlay stitching.

The material is too thick or hard.

Use material suitable for embroidery.

Bobbin is deformed and it touches the needle.

Replace the bobbin.

Bad quality of needle, mismatching to

embroidery condition

Use good quality needle. Use needle that fits to

embroidery condition.

Vibration of the machine is big.

Adjust leveling.

TFMX, TEMX-C

Abrasion of needle catcher of rotary hook.

TFMS

Abrasion of shuttle hook driver.

Common to models

The gap between needle and hook point is not suitable. Bad needle location. Play

of needle bar case (in right and left direction) is big. The floor vibrates. There is a

play on the fringe of the frame.

Cause

Troubleshooting

Bad thread tension

Adjust tension.

Quality of thread is bad. Poor thread flow

Use good quality thread. Spray silicone.

Density of design data does not match with

material and/or thread.

Correct data.

Bad frame attaching and fixing of the fabric

Attach the frame correctly. Fix the fabric firmly.

Thread, needle and/or size of needle plate do not

match with embroidery.

Make combination that fits to design data/material.

R.P.M. is too high.

Decrease R.P.M.

Содержание TEMX-C Series

Страница 13: ...To search from the menu key ...

Страница 25: ...Inspection before starting work 12 Chapter 1 ...

Страница 39: ...How to use each part 26 Chapter 2 ...

Страница 40: ... E 1 2 3 4 5 6 7 8 9 10 11 27 PT10 Chapter 3 Screen 1 Screen display 28 2 Message display 31 ...

Страница 104: ...To stop the machine 91 1 2 3 4 5 6 7 8 9 10 11 Chapter 5 PT10 4 To make Frame Limit Setting effective YES ...

Страница 147: ...Other functions that must be remembered 134 Chapter 5 ...

Страница 171: ...To move the frame to the position registered 158 Chapter 6 ...

Страница 189: ...Design stored in USB memory 176 Chapter 7 ...

Страница 204: ...Functions concerning optional device 191 1 2 3 4 5 6 7 8 9 10 11 Chapter 8 4 To use air compressor YES RR07 ...