5

missprints and technical changes reserved

Instruction & Operating Manual

TA-15/6P...200/6P

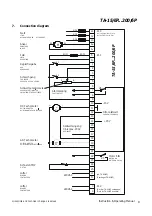

5.1 Armature feedback control (UA-controlled)

1)

Jumper

VI

must be installed if a controlled decelaration at drive stop is requested. For

Emergency

off

the connection between terminals 24 and 25 must be opened (Quick-stop). The drive will be

locked immidiately.

2)

Check all connections with an Ohm-meter for grounds.

3)

Install jumpers

I

and

VII

and also resistor R82 (22 KOhm).

4)

Check if line voltage corresponds with voltage indicated on the type marking. Select applicable

frequency, 50 Hz or 60 Hz with frequency-switch.

5)

Switch on line voltage. The following LED must light up:

LED 8

green

Line on

LED 5

green

+15V

LED 2

green

-15V

The diodes LED 4 (red) and the six diodes LED 1 (clear) will only light up briefly.

6)

Measure field voltage at terminal F+ and F- with a Multimeter (moving coil meter with at least 330

Ohm/Volt) 270V at 400V or 155V at 230V line-voltage. Measure voltage at potentiometer (terminal

5- and 6+) 10 V d.c. Set min. speed potentiometer during this measurement fully counter

clockwise.

7)

Potentiometer P4

Acceleration time, set in center position

Potentiometer P2

Deceleration time, set in center position

Potentiometer P3

IxR Compensation, set fully counter clockwise

Potentiometer P8

Stability, set in center position

Potentiometer P7

Jog speed, set fully counter clockwise

Potentiometer P10

Delay time, set fully clockwise

8)

Switch on the drive, LED 11 yellow (Drive on) and LED 9, green (drive release) will light up. When

the speed potentiometer is turned in clockwise direction, the armature voltage and the motor

speed respectively, will increase. This causes the six clear diodes LED 1 (Thyristor triggering) to

light up. Adjust potentiometer P9 (max. speed) for the requested armature voltage/motor speed.

Now set speed potentiometer fully counter clockwise, the output voltage must drop back to 0V.

Now adjust potentiometer P6 for the requested minimum speed.

9)

Switch off drive, Jog speed switch on.(LED 7 and LED 9 will light up). Adjust the requested jog

speed with potentiometer P7 (Jog speed).

10)

Adjust I x R compensation. Check for an apoprox equal speed with and without motor load in the

lower speed range. If the potentiometer is turned in clockwise direction the speed under load will

increase.

If the compensation potentiometer is set too high, the drive will become unstable.

Caution!

Do not use

any

Mega-Ohm-meter, buzzer or similar test instruments.

Test instruments must be galvanically seperated from a.c. line.

5.

Functional tests and preliminary adjustments before operation