2. Minimize pipe strain on pump by using pipe hangers

on the suction and discharge lines.

3. Position vertical and horizontal piping so bolt-holes on

pump and companion flanges match. Do not force the

suction and discharge lines into position. This may cre-

ate excess stress on the pump casing and flanges.

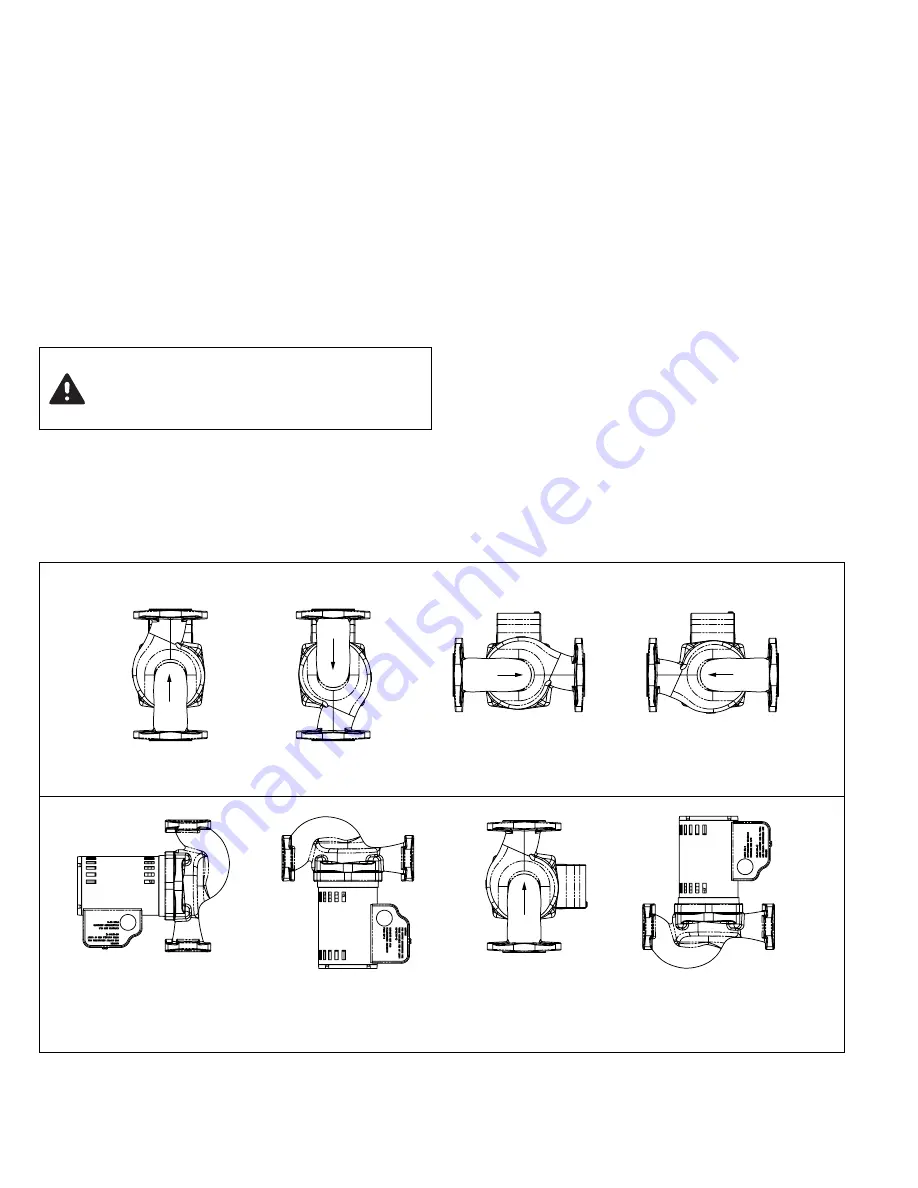

B. Mounting Position:

• Always install pump with the motor shaft in the hori-

zontal position and the capacitor/conduit box oriented

on top of the motor housing, as shown in Fig. 1.

• Standard pump body mounting position is with the flow

in the up-discharge direction (body position #3). The

pump body may be field-rotated in any direction to

accommodate system piping and flow direction.

• Be sure to align the arrow on the casing with desired

flow direction.

C. Electrical Wiring:

• All electrical wiring must be installed by a licensed

electrician in accordance with local and national codes

and regulations.

• Electrical supply and grounding wires must be suitable

for at least 90ºC (194ºF).

• 1400 Series circulators are thermally protected and do

not require external overload protection.

1. Be sure all electrical power to pump is disconnected

and locked-out before proceeding with wiring.

2. Loosen capacitor/conduit box screw and remove cover.

3. Attach appropriate size connector to one of the two

knock-out holes in the capacitor/conduit box.

4. Using minimum 18 AWG wire, connect the hot and

neutral leads from the electrical supply to the respec-

tive black and white leads in the capacitor box.

5. Connect the ground wire to the green ground screw in

the capacitor box.

6. Replace capacitor/conduit box cover.

7. Insert plastic plug provided in unused knock-out hole.

RECOMMENDED

NOT RECOMMENDED

FLOW

FLOW

FLOW

FLOW

FLOW

CAUTION: Do not support, suspend or brace

pump motor or early failure may result.

Support provided by casing is sufficient for

structural integrity of pump

Fig. 1 – Installation Positions