English

36 SYSHRW

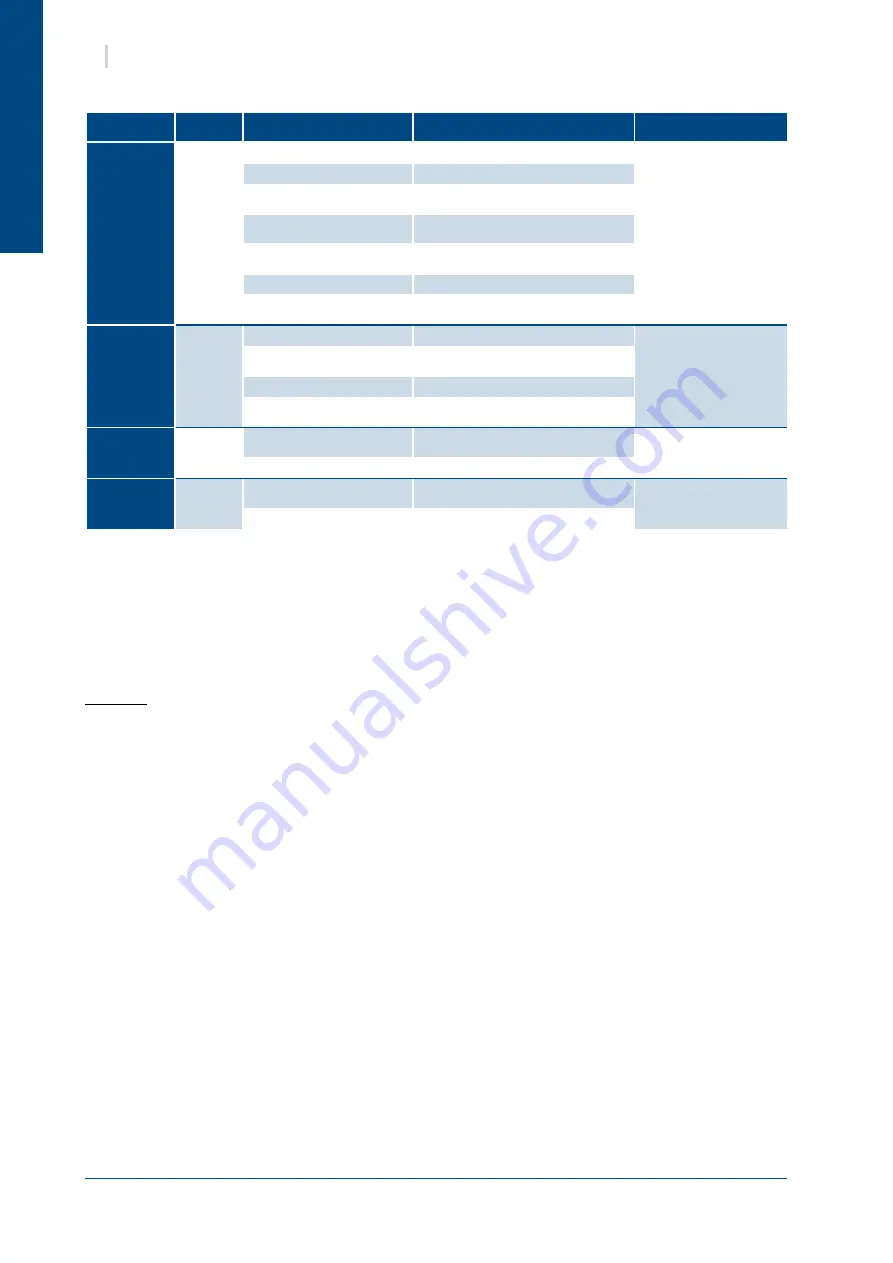

17.2.3. HEATING MODE

FAULT

LED LARM CODE POSSIBLE CAUSE

CORRECTIVE ACTION

ACTION FOR CANCELLING FAULT CODE

AFTER CORRECTION

High pressure or

water flow fault

100000000

1 flashe

Insufficient airflow

Check proper fan operation.

Cut the mains power supply for

5 seconds, and then reconnect.

Clogged filters.

Clean or replace the filters.

Too high aeraulic pressure loss due to an

obstruction in the intake duct.

Test the aeraulic network.

Insufficient water flow or no water flow at

the level of the appliance.

Test the flow from the pump on the main loop.

Stop cock or water inlet valve shut (**)

Test the valve electrical supply. Test the direction of

flow. Open the valve.

Faulty pressure differential

Check electrical connections.

Pressostat defective, broken wire or short

circuit.

Check the proper connection of the HP pressostat and/or

conduct a continuity test.

Low pressure

110000000

2 flashes

Insufficient water flow in the appliance.

Test the pump flow at the level of the main loop.

The fault code is automatically

cancelled after correction(***).

The LED stops flashing and the green

light remains on.

Pressostat sensor defective, broken wire

or short circuit.

Check the proper connection of the LP pressostat and/or

conduct a continuity test.

Refrigerant leak.

Find and repair any leaks on the pipe circuits.

Water inlet valve closed (**)

Test the valve electrical supply. Test the direction of

flow.

Low water

temperature limit

111110000

5 flashes

Hot water loop temperature < 13°C .

Test the temperature at the level of the main loop.

The fault code is automatically

cancelled after correction

(***).

The LED stops flashing and the green

light remains on.

Insufficient water flow.

Test the water flow at the level of the main loop.

High water

temperature limit

111111000

6 flashes

Hot water loop temperature > 35°C

Test the temperature at the level of the main loop.

The fault code is automatically

cancelled after correction

(***).

The LED stops flashing and the green

light remains on.

Insufficient water flow.

Test the water flow at the level of the main loop.

(**)

This case only concerns installations where the valve is fitted on the water loop upstream of the

machine.

(***)

Lockout if 3 faults within 1 hour. Cut the mains power supply for 5 seconds, and then reconnect.

Note

: More than 2 alarm codes can be activated at the same time. Only the last code detected will be

visible on the RCL control module or on the STORM2 circuit board. After the source of the first alarm code

is resolved, the second code will appear, and so on until all the faults are cancelled and until the LED stops

flashing.

Example:

111 000 000

²

1 corresponds to one flash of the LED situated on the STORM2 circuit board or on the RCL.

²

0 indicates that there is no flash.

In this precise case, there will be 3 flashes, then the flashing will stop for a while (a few seconds), then there

will be 3 further flashes and so on until the fault is cancelled. Then the LED is off in OFF mode, and fixed on

in ON mode.

18. IN-WARRANTY RETURN MATERIAL PROCEDURE

19. SERVICE AND SPARE PARTS ORDER

Material must not be returned without permission of our After Sales Department.

To return the material, contact your nearest sales office and ask for a "return voucher". This return voucher

shall be sent out with the returned material and shall contain all necessary information concerning the

problem encountered.

The return of the part does not constitute an order for replacement. Therefore, a purchase order must be

entered through your nearest distributor or regional sales office. The order should include part name, part

number, model number and serial number of the unit involved.

Following our personal inspection of the returned part, and if it is determined that the failure is due to faulty

material or workmanship, and in warranty, credit will be issued on customer's purchase order. All parts shall

be returned to our factory, transportation charges prepaid.

The model number, the confirmation number and the unit serial number indicated on the name plate must

be provided whenever service works or spare parts are ordered.

For any spare part order, indicate the date of unit installation and date of failure. Use the part number

provided by our service spare parts, if it not available, provide full description of the part required.

Содержание SYSHRW Series

Страница 1: ...Water source heat pump Installation and maintenance manual 5 3 â 17 2kW 5 8 â 21 5kW 019 072 SYSHRW ...

Страница 2: ......

Страница 39: ...APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO ...

Страница 40: ...II SYSHRW APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO ...

Страница 42: ...SE 4250 A N724 3991283 HRW 19 µBMS WIRING DIAGRAM IV SYSHRW APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO 19 ...

Страница 43: ...SE 4484 N724 3991387 HRW 19 µBMS WIRING DIAGRAM V SYSHRW APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO 19 MODBUS ...

Страница 48: ...SE 4253 N724 3991286 HRW 72 µBMS WIRING DIAGRAM X SYSHRW APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO 72 ...

Страница 50: ...XII SYSHRW APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO ...

Страница 53: ......