SYNETICA enLink OAQ

Quick Start Guide Rev 1.5

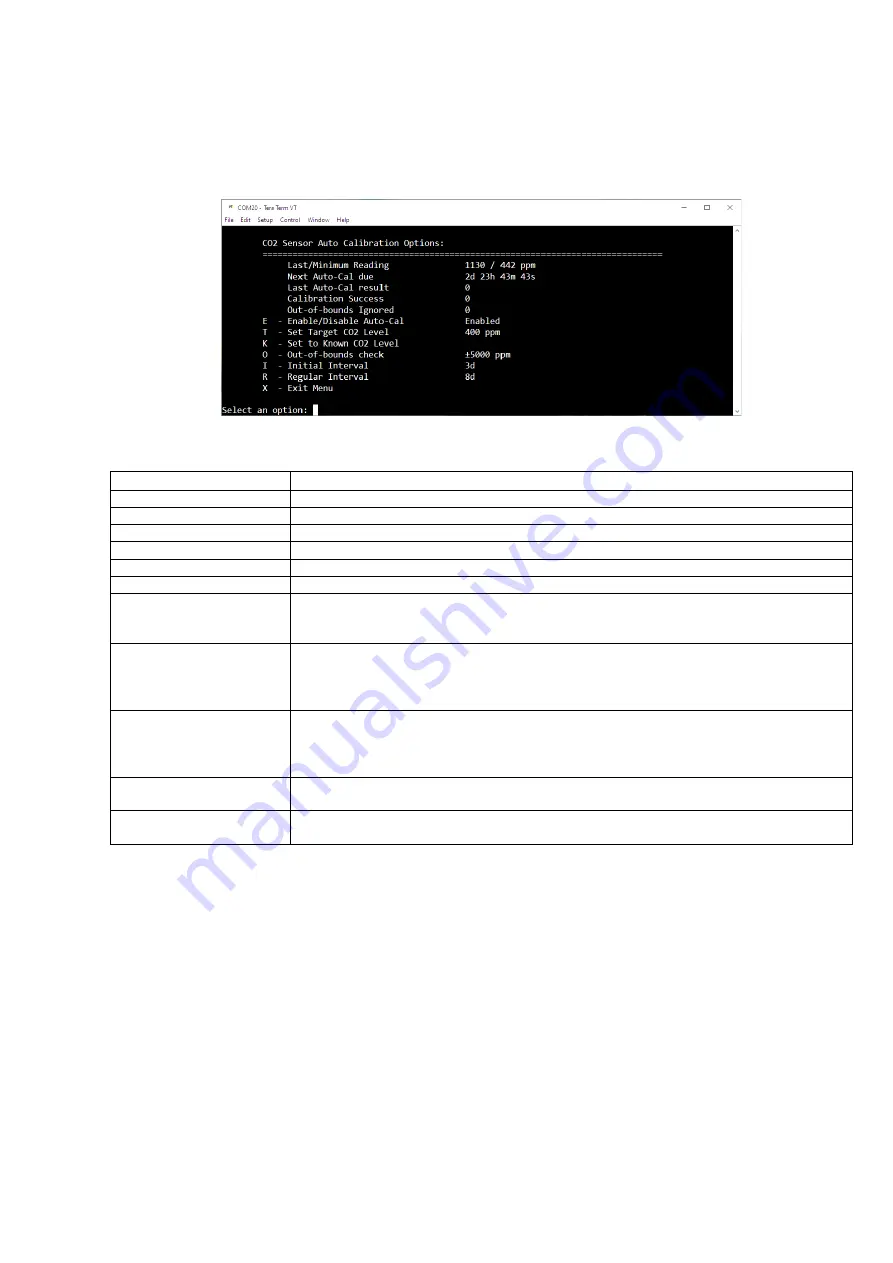

CO

2

Sensor Auto Calibration Configuration

To view and set CO

2

sensor calibration information, enter

c

and the screen below will show.

Please see the table below for information on each menu item.

Menu Item

Description / details

Last/Minimum Reading

Shows the last CO

2

value read and the minimum CO

2

value read since the last auto calibration.

Next Auto-Cal due

Shows when the next autocalibration routine will occur

Last Auto-Cal result

Shows the value of the last auto calibration result. Used internally by the sensor.

Calibration Success

This shows the total number of successful auto calibrations since the device was powered up.

Out-of-bounds Ignored

Shows the number of times that auto calibration did not run due to the Out Of Bounds setting.

E - Enable/Disable Auto-Cal

Enables or disables the auto calibration routine.

T - Set Target CO2 Level

This is the known CO

2

corresponding to the minimum value the sensor has read since power-up or

last calibration. It is normally 'fresh air' or the lowest level when the building is unoccupied

overnight or at weekends. Typically this is 400 ~ 450 ppm.

K - Set to Known CO2 Level

This will re-calibrate the zero point of the sensor to a known gas concentration. The sensor should

be placed in this gas concentration and allowed to stabilise.

This command runs in the background and will take 8 to 10 seconds to complete.

As an example, fresh air is typically around 400 ~ 450 ppm.

O - Out-of-bounds check

The Out-of-bounds value is used to ignore the calibration if the minimum value the sensor has read

is not within a sensible range of the target concentration level.

So, if the target concentration level is 400, the Out-of-bounds value is ±50 and the minimum

reading is 451 (or more), the calibration routine is ignored.

I - Initial Interval

It is possible for the first auto-calibration to take place more quickly than the regular auto-

calibration events. This can be useful to stabilise the readings quickly after installation.

R - Regular Interval

This is the standard calibration interval, it is set to 8 days by default to accommodate a week long

period where the minimum sensed CO

2

level should have fallen to background levels.

The CO

2

sensor needs to be exposed to fresh, clean air periodically for the auto calibration to be successful. Most

occupied areas are unoccupied for some time during a week-long period, typically at night, or at the weekend and

therefore the auto calibration runs every 8 days by default. Background CO

2

levels are typically around 400-450 ppm, if

the background CO

2

level is known to be a different value then this can be set in the

“

Set Target CO

2

Level

”

parameter

If a unit is placed in an area where the CO

2

level may not fall below a certain level, e.g. 450ppm, during the calibration

interval

then the “Out

-of-

bounds check” parameter can be set so that the auto calibration routine does not run. As an

example, if an area is continuously occupied for a long period and the minimum CO

2

reading does not fall below, say

450ppm, then it is undesirable to run the autocalibration routine based on a target of 400ppm. In this case, if the

“

Set

Target CO2 Level

”

is set to 400ppm and the

“

Out-of-bounds

check”

value is set to +/-50 ppm then the autocalibration

routine will not run unless the minimum read value falls below 451ppm in the interval.

Содержание enLink OAQ

Страница 10: ...SYNETICA enLink OAQ Quick Start Guide Rev 1 5 ...